Electrical System Maintenance for Trains: Best Practices and Challenges

Trains rely on their electrical systems to run smoothly and safely. These systems power the train and keep passengers and freight safe. This article will cover the best ways to maintain train electrical systems and the challenges you might face.

Train electrical systems are complex, with many parts that need special care. Knowing how these systems work is key to keeping them running well. It’s also important to follow safety rules and handle high-voltage gear carefully.

Key Takeaways

- Understanding train electrical systems is vital for good maintenance.

- Keeping people and equipment safe is a top priority.

- Regular checks and maintenance can prevent problems and make systems last longer.

- Being able to fix electrical issues quickly is crucial.

- Dealing with old infrastructure and tight budgets requires creative solutions and planning.

Understanding Train Electrical Systems

Trains rely on intricate electrical systems for power distribution, control of components like lighting and heating, and overall functionality. Ensuring these systems operate smoothly is crucial for the safety and reliability of train operations. Companies like Wyss&Lila AG specialize in the engineering and modernization of such systems, focusing on sustainable and advanced railway solutions. To learn more about their expertise, you can visit https://wysslila.com/.

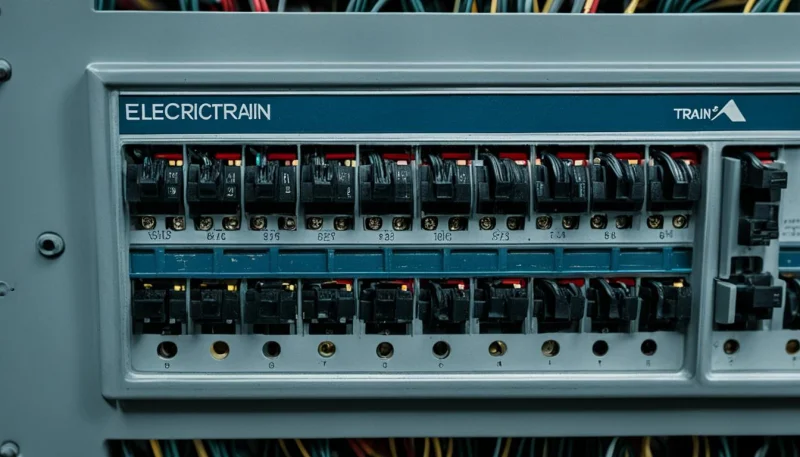

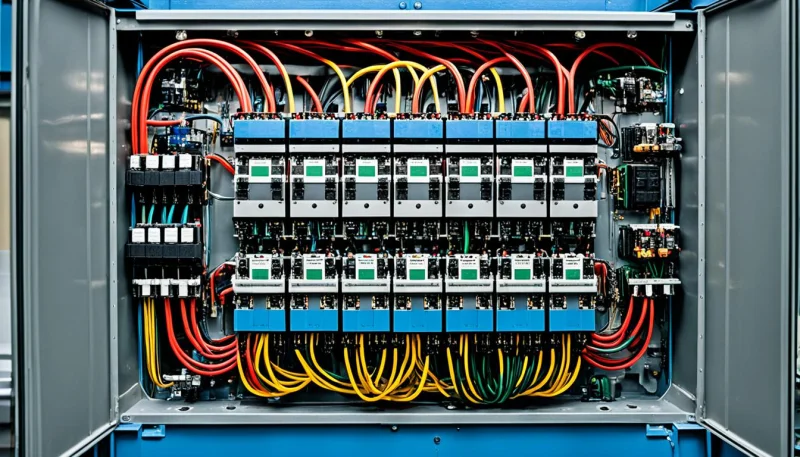

Components and Functions

The main parts of a train’s electrical system are the power generators, distributors, and controllers. Generators turn mechanical energy into electricity for the train and its systems. This electricity is then sent to different parts of the train, like lights and heating systems. The control system makes sure all these parts work together smoothly and safely.

Safety Considerations

Keeping train electrical systems safe is very important. There are strict rules to protect workers and passengers. These rules include things like proper grounding and insulation to avoid electrical dangers. Following these rules and checking the train electrical system components and locomotive electrical system functions often is key to preventing accidents and keeping the railway safe.

| Train Electrical System Components | Locomotive Electrical System Functions |

| Power generation (alternators, generators)Power distribution (wiring, cables, transformers)Control systems (circuit breakers, relays, sensors)Lighting and signaling systemsPassenger amenities (HVAC, entertainment) | Powering the locomotive’s propulsion systemProviding electricity for onboard systemsControlling and monitoring locomotive operationsEnsuring reliable train power distributionMaintaining proper locomotive control systems |

“Electrical systems are the lifeblood of modern trains, enabling their efficient and safe operation. Understanding these systems is crucial for effective maintenance and improvement.”

Preventive Maintenance Strategies

Keeping train electrical systems reliable and long-lasting is crucial. Effective preventive maintenance is key. Railway operators must watch closely and do regular maintenance to spot and fix problems early.

Scheduled Inspections

Regular checks of the train’s electrical system are vital for maintenance. These checks look at train electrical components, railway electrical system connections, and how well the system works. Catching small issues early helps avoid big, expensive problems later.

- Routine visual inspections of electrical panels, wiring, and connections

- Comprehensive testing of locomotive electrical systems, including voltage, amperage, and resistance checks

- Predictive maintenance techniques, such as infrared thermography, to detect hidden issues

- Detailed documentation and record-keeping of all inspection findings and maintenance activities

Following a good locomotive scheduled maintenance plan means doing rail electrical system inspection and train electrical system troubleshooting early. This lowers the chance of sudden breakdowns and keeps the railway’s electrical systems reliable.

| Preventive Maintenance Task | Frequency | Purpose |

| Visual Inspection | Weekly | Identify visible issues or wear and tear |

| Electrical System Testing | Monthly | Detect any performance degradation |

| Infrared Thermography | Quarterly | Identify hidden issues through heat signatures |

| Comprehensive Overhaul | Annually | Ensure optimal system performance and reliability |

A strong train electrical preventive maintenance plan helps railway operators. It improves railway electrical system upkeep, cuts down on expensive train electrical system troubleshooting, and keeps trains running well.

Diagnostic Testing and Troubleshooting

Keeping the electrical systems of trains safe and reliable is key. To fix electrical issues, it’s vital to use thorough diagnostic tests and troubleshooting steps. These methods help find the main cause of problems fast, reducing downtime and making critical train electrical system diagnostics, railway electrical troubleshooting, locomotive fault detection, rail electrical system testing, and train control system diagnostics last longer.

Insulation resistance testing is a crucial tool in the railway world. It checks how well electrical surfaces are insulated. By doing this test often, technicians can spot problems early. This helps avoid big repairs and keeps trains running safely.

Along with insulation testing, railway electrical troubleshooting also means checking circuits and parts closely. Technicians look at each circuit and part to find where locomotive fault detection is happening. This lets them fix problems right away and stop them from happening again.

For better troubleshooting, railway teams should have a clear plan. Keeping track of past problems and how they were solved is important. They should also have set ways for rail electrical system testing and train control system diagnostics. This helps them work faster, get better results, and keep the railway’s electrical systems reliable.

“Proactive diagnostic testing and a structured troubleshooting approach are essential for maintaining the electrical systems of trains, ensuring safe and efficient operations.”

Electrical System Maintenance for Trains: Best Practices and Challenges

Streamlining Maintenance Procedures

Keeping the electrical systems of trains running smoothly is key to a well-functioning railway network. To make this easier, it’s important to follow best practices. These practices help streamline maintenance and tackle common issues.

One effective strategy is to use standardized processes. This means having the same steps for checking, fixing, and maintaining trains. It makes teams work better together and lowers the chance of mistakes.

Using special tools and equipment also boosts maintenance efficiency. For example, advanced diagnostic tools help find and fix problems fast. This cuts down on delays and makes the system work better.

It’s also vital to keep improving how maintenance is done. Encouraging team members to share ideas and find new solutions helps make maintenance better. This leads to more efficient ways of doing things.

| Best Practices for Train Electrical Maintenance | Challenges in Railway Electrical System Maintenance |

| Standardized maintenance proceduresSpecialized tools and equipmentContinuous improvement mindsetEffective communication and collaborationData-driven decision-making | Aging infrastructureBudgetary constraintsSkill gaps and training requirementsCompliance with safety regulationsUnpredictable system failures |

By following these best practices and tackling maintenance challenges, railway operators can make their operations more efficient, reliable, and safe. This improves the experience for passengers and freight transport.

Overcoming Common Challenges

Keeping train electrical systems running smoothly is tough, with many hurdles to jump over. Aging infrastructure and tight budgets are two big problems rail operators face. These issues can slow down efforts to modernize and keep train electrical systems reliable. But, with careful planning and new ideas, these problems can be solved.

Aging Infrastructure

Many rail networks use old electrical parts and systems that need updating. Challenges in train electrical maintenance often come from trying to keep these old systems running. As time goes on, these parts can fail more often, making it hard to find new ones. Rail operators must focus on railway aging infrastructure and plan ahead to keep trains safe and running well.

Budgetary Constraints

Upgrading train electrical systems costs a lot of money, and locomotive budget constraints can slow things down. Rail operators must find a balance between what they need to do and what they can afford. They should focus on the most important upgrades and look for ways to save money. Things like public-private partnerships and government funding can help with train electrical system modernization.

By tackling these common challenges, rail operators can make sure their train electrical systems work well. This makes the passenger experience better and helps rail networks stay sustainable.

Training and Certification Requirements

Getting the right training and certification is key for train electrical systems. Railway workers need a wide range of skills and knowledge. They must know how to fix and maintain the electrical parts of trains safely and efficiently.

To become a railway technician, you usually start with formal education in electrical engineering or a similar field. Then, you get specialized training in how trains’ electrical systems work.

Technicians also need to know about safety rules and how to keep train control systems safe. They keep learning new things through programs from industry groups and government agencies. This keeps them up-to-date with the latest in their field.

| Training Requirement | Certification Requirement |

| Electrical engineering or related degree | Railway Technician Certification |

| Hands-on training in locomotive electrical systems | Train Control System Technician Qualification |

| Coursework in rail electrical system upkeep skills | Continuing Education Credits |

By focusing on training and certifying their teams, rail companies can make sure their electrical systems are reliable and safe. This also helps build a workforce that can handle the changing needs of the industry.

“Properly trained and certified technicians are the backbone of a robust electrical system maintenance program for trains. Their expertise and commitment to safety are essential for keeping our railways running at their best.”

Emerging Technologies and Innovations

The railway industry is always changing, thanks to new technologies that make train electrical systems better. Predictive maintenance and condition monitoring systems are two big changes. They are changing how train operators keep electrical systems running well.

Predictive Maintenance: Proactive Reliability

Predictive maintenance is a big deal. It uses advanced analytics and sensor data to predict when equipment might fail. This way, rail operators can fix problems before they happen. It cuts down on downtime and makes systems more reliable.

Condition Monitoring Systems: Intelligent Diagnostics

Condition monitoring systems are getting better fast. They track and analyze important train electrical system info in real-time. With sensors, they collect data on things like voltage, current, temperature, and vibration. This helps maintenance teams plan better and keep electrical systems running longer.

Using predictive maintenance and condition monitoring together is changing the game. It lets operators move from fixing problems after they happen to fixing them before they start. By using train electrical system innovations, maintenance teams can make systems more reliable, cut costs, and work more efficiently.

| Technology | Key Benefits |

| Predictive Maintenance | Reduces unplanned downtimeOptimizes maintenance schedulesExtends the lifespan of electrical components |

| Condition Monitoring Systems | Provides real-time data on system performanceEnables proactive maintenance interventionsImproves overall system reliability and safety |

As the railway industry keeps investing in these railway maintenance technologies, train operators can expect better efficiency, cost savings, and improved electrical system performance.

Environmental Impact Considerations

As we focus more on being green and caring for our planet, looking at the environmental impact of train electrical systems is key. The railway industry is a big part of our future transport, and going green is crucial to cut down on pollution.

One big worry is how locomotive energy efficiency works. Trains use a lot of energy, mainly electricity, for their systems and controls. By using new tech and railway sustainable maintenance practices, we can use less energy and cut down on harmful emissions.

Also, taking care of the train control system environmental footprint is vital. This means safely getting rid of dangerous materials like batteries and oils, and making less waste when fixing and maintaining trains. Using the circular economy and finding new ways to handle waste helps the industry be kinder to the planet.

By thinking about the environment in a big way, the railway can show the way to sustainable transport. We need to keep innovating, following best practices, and working together to make the future of rail greener.

“The railway industry has a unique opportunity to set the standard for sustainable transportation. By prioritizing the environmental impact of train electrical systems, we can pave the way for a cleaner, more efficient rail network.”

- Invest in energy-efficient technologies for their electrical systems and control mechanisms

- Adopt sustainable maintenance practices that minimize waste and environmental damage

- Collaborate with suppliers and partners to reduce the overall carbon footprint of rail operations

- Continuously monitor and improve environmental performance metrics to drive continuous improvement

By taking these steps, the railway industry can pave the way for a greener future. It will set an example for other transport areas to follow.

Safety Protocols and Regulations

Keeping train electrical systems safe means following strict safety rules and regulations. It’s crucial to keep maintenance workers safe. This section talks about the key things that make sure they stay safe and keep the rail network safe too.

Standard Operating Procedures

Train electrical system safety protocols and railway maintenance regulations are key to safe work on trains. They set out clear steps and best ways to do maintenance, repair, and fix problems. These rules cover everything from using personal protective gear to following lockout-tagout steps. They help lower risks and keep workers safe.

- Comprehensive safety training for all maintenance personnel

- Rigorous inspection and testing of electrical systems before work starts

- Following locomotive electrical system safety standards and best practices

- Clear emergency response plans if something goes wrong

Groups like transportation authorities and industry groups help make and enforce these rail electrical work procedures and train control system compliance rules. Maintenance teams need to keep up with new rules and guidelines to keep their work safe.

“Putting safety first is not just smart, it’s a must in the rail industry. Having strong safety rules and good training is key to keeping our workers safe and serving our communities.”

By sticking to safety rules and regulations, rail maintenance teams can reduce risks, protect their workers, and make sure train electrical systems work safely and reliably.

Partnering with Skilled Technicians

Keeping train electrical systems running well needs skilled train electrical maintenance technicians. It’s key to work with pros who know their stuff, can solve problems, and have real-world experience. This ensures locomotive electrical system experts and train control system specialists do their jobs safely and reliably. But finding and keeping top railway skilled labor is hard.

Train electrical systems are complex and need a lot of knowledge. Rail electrical system contractors must know how to fix a variety of problems, from small issues to big ones. They must work well, safely, and follow the rules.

To keep train electrical systems in good shape, railway companies need a skilled team. This means offering good pay, training, and a place where people can grow and be happy in their jobs.

“The key to reliable train electrical system maintenance lies in the expertise and dedication of our technicians. We strive to attract and retain the best talent in the industry, ensuring our trains run safely and efficiently.”

Working with skilled train electrical maintenance technicians helps railway operators make the most of their electrical systems. This means less downtime and better service for passengers and freight customers.

| Skill Set | Importance |

| Electrical engineering expertise | Essential for understanding the complex train electrical systems and troubleshooting issues |

| Hands-on maintenance experience | Crucial for performing preventive maintenance, repairs, and system upgrades |

| Problem-solving abilities | Necessary for diagnosing and resolving electrical system problems efficiently |

| Safety-conscious approach | Vital for ensuring the safe operation of trains and protecting the wellbeing of technicians |

| Commitment to continuous learning | Important for staying up-to-date with emerging technologies and best practices |

Continuous Improvement and Quality Control

Keeping train electrical systems in top shape is a never-ending task. It needs a strong focus on getting better and keeping quality high. By using performance metrics, analyzing data, and getting feedback, train operators can make their maintenance better. This ensures trains run well and reliably for a long time.

Performance Metrics and Data-Driven Insights

Important performance indicators (KPIs) help watch and improve rail system performance. Things like mean time between failures, maintenance costs, and energy use give clues about how well train electrical parts work. By looking at these locomotive electrical system KPIs often, quality control teams can spot areas to get better. They can then focus maintenance efforts and make smart choices based on data.

Keeping an eye on rail electrical system performance is key for safety and reliability. Tracking system uptime, response times, and other important metrics lets railways fix problems early. This reduces service interruptions and keeps passengers happy.

A mindset of continuous improvement and changing maintenance based on data is crucial for train electrical system maintenance. This way, innovation grows, teams feel empowered, and long-term railway quality control practices improve. Both the company and its customers benefit from this approach.

| Key Performance Indicator (KPI) | Description | Benchmark |

| Mean Time Between Failures (MTBF) | The average time between unexpected failures of electrical components | 12,000 hours |

| Maintenance Cost per Mile | The total cost of electrical system maintenance divided by the distance traveled | $0.50 per mile |

| Energy Efficiency | The ratio of output power to input power, measured in kilowatt-hours per mile | 12 kWh/mile |

“Continuous improvement is not about the things you do well – that’s work. Continuous improvement is about removing the things that get in the way of your work. The headaches, the irritations, the things that slow you down, that’s what continuous improvement is all about.”

– Don Tapping, Author and Lean Six Sigma Expert

Cost-Benefit Analysis

Investing in train electrical systems has big financial effects. Railway operators can make smart choices by looking at costs and benefits. This helps them use resources well and pick the best maintenance strategies.

It’s important to think about how long equipment lasts and how efficient it uses energy. New, efficient parts can save money over time by using less energy and needing less maintenance. Also, a reliable electrical system means less downtime and better performance. This can lead to more work and more money.

| Metric | Current System | Upgraded System |

| Energy Consumption (kWh/year) | 250,000 | 180,000 |

| Maintenance Costs ($/year) | 50,000 | 35,000 |

| Downtime (hours/year) | 500 | 250 |

| Estimated ROI (5-year period) | – | 25% |

The table shows how upgrading the train electrical system can save money and increase the return on investment (ROI). By spending on train electrical system maintenance cost-benefit and railway electrical system investment, operators can better manage their rail electrical system budget. This leads to more money over time from locomotive electrical upgrades ROI and train control system lifecycle cost analysis.

“Investing in the maintenance and improvement of train electrical systems can unlock significant long-term savings and operational benefits.”

Doing a detailed cost-benefit analysis is key for railway operators. They should think about how long things last, how efficient they are, how often they break down, and the savings over time. This helps them use their resources wisely and make the best choices for maintenance and upgrades.

Conclusion

As we wrap up our deep dive into train electrical system maintenance, it’s clear that a comprehensive approach is key. This approach ensures trains run safely, reliably, and efficiently. It focuses on preventive maintenance, diagnostic testing, and using new tech like predictive maintenance and condition monitoring systems.

For railway upkeep, a proactive, data-driven strategy is crucial. It tackles the challenges of old infrastructure and tight budgets. By adopting new solutions and a culture of constant improvement, railways can make their electrical systems better. This boosts the performance of their train control systems.

Challenges in maintaining and upgrading locomotive electrical systems are ongoing. Yet, the need to optimize rail electrical systems is crucial. It affects the safety, efficiency, and greenness of the whole railway network. Skilled technicians and strong safety rules are key to keeping these systems running smoothly.

FAQ

What are the key components and functions of train electrical systems?

Train electrical systems have many parts like power generation, distribution, and control systems. Each part plays a key role in making trains run safely and efficiently.

What safety considerations are important when maintaining train electrical systems?

Keeping train electrical systems safe means following strict safety rules. This includes wearing protective gear, following set procedures, and having emergency plans ready. It helps keep maintenance workers and passengers safe.

How can railway operators implement effective preventive maintenance strategies for their electrical systems?

To keep train electrical systems running well, railway operators should do regular checks and maintenance. They should also watch for problems early to fix them before they get worse. This keeps these important systems reliable and long-lasting.

What diagnostic testing and troubleshooting techniques are used to identify and resolve electrical issues in trains?

For train electrical problems, maintenance uses tests like insulation checks and circuit analysis. These help find and fix electrical issues fast. This way, trains can keep running safely without long delays.

What are some best practices for streamlining maintenance procedures for train electrical systems?

To make maintenance smoother, use standard processes and special tools. Encourage a culture of always getting better. Good communication and teamwork among maintenance teams also helps.

What are the common challenges faced in maintaining the electrical systems of trains, and how can they be overcome?

Dealing with old infrastructure and tight budgets is common. To overcome this, plan ahead, find new solutions, and set priorities. This ensures trains run well without spending too much.

What are the training and certification requirements for personnel responsible for maintaining train electrical systems?

People who work on train electrical systems need special training and certification. This makes sure they know the technical stuff, have practical skills, and follow the rules and standards.

How are emerging technologies and innovations shaping the maintenance of train electrical systems?

New tech like predictive maintenance is changing how trains are kept in good shape. It helps improve performance, cut downtime, and make systems more reliable.

What environmental impact considerations are important in the maintenance of train electrical systems?

Looking after train electrical systems means thinking about the environment too. This includes using less energy, reducing emissions, and managing waste better. Using green maintenance methods and tech helps lessen the railway’s environmental impact.

What safety protocols and regulations govern the maintenance of train electrical systems?

There are strict safety rules and regulations for train electrical maintenance. This includes following standard procedures, using protective gear, and sticking to industry standards and guidelines.

Why is it important to partner with skilled technicians for train electrical system maintenance?

For train electrical system maintenance, it’s key to work with skilled technicians. They have the right knowledge, problem-solving skills, and experience to keep these systems running safely and reliably.

How can railway operators implement continuous improvement and quality control measures for their electrical system maintenance practices?

To keep improving and maintaining quality, railway operators should track performance, analyze data, and use feedback. This encourages ongoing learning and innovation to make these systems better over time.

How can a cost-benefit analysis help railway operators make informed decisions about their train electrical system maintenance investments?

A detailed cost-benefit analysis helps railway operators decide on maintenance investments. It looks at things like equipment life, energy use, downtime reduction, and long-term savings. This helps them use resources wisely and choose cost-effective maintenance plans.

Ti potrebbe interessare:

Segui guruhitech su:

- Google News: bit.ly/gurugooglenews

- Telegram: t.me/guruhitech

- X (Twitter): x.com/guruhitech1

- Bluesky: bsky.app/profile/guruhitech.bsky.social

- GETTR: gettr.com/user/guruhitech

- Rumble: rumble.com/user/guruhitech

- VKontakte: vk.com/guruhitech

- MeWe: mewe.com/i/guruhitech

- Skype: live:.cid.d4cf3836b772da8a

- WhatsApp: bit.ly/whatsappguruhitech

Esprimi il tuo parere!

Ti è stato utile questo articolo? Lascia un commento nell’apposita sezione che trovi più in basso e se ti va, iscriviti alla newsletter.

Per qualsiasi domanda, informazione o assistenza nel mondo della tecnologia, puoi inviare una email all’indirizzo [email protected].

Scopri di più da GuruHiTech

Abbonati per ricevere gli ultimi articoli inviati alla tua e-mail.