Fundamentals of Motor Circuit Protection: Key Principles & Devices

Motor circuit protection is essential for ensuring the safe and reliable operation of electrical motors. This aspect of electrical engineering focuses on protecting motors from overloads, short circuits, and faults, which can lead to equipment damage or failure. Proper motor circuit protection not only extends the lifespan of the motor but also enhances safety by minimizing the risk of fire hazards.

Understanding the differences between various types of protection, such as overload and overcurrent protection, is crucial for engineers and technicians. These protections work together to prevent potential damage from excessive current or heat that can occur during normal operation or due to unexpected faults. By selecting the right devices, like fuses and circuit breakers, and adhering to regulations like the National Electrical Code (NEC), they ensure a motor is adequately safeguarded.

As motors continue to be vital components in countless applications, from industrial machinery to home appliances, having a solid grasp of motor circuit protection fundamentals becomes increasingly important. This knowledge allows professionals to design systems that are not only efficient but also safe and compliant with regulatory standards.

Core Principles of Motor Circuit Protection

Motor circuit protection is essential for ensuring that motors operate safely and efficiently. It involves understanding different types of protection mechanisms, addressing common faults, and the repercussions of failing to implement proper safeguards.

Objectives and Importance

The main objectives of motor circuit protection are to prevent damage and ensure safety. Key protection types include:

- Overload Protection: This safeguards motors from running at excessive current, which can lead to overheating.

- Short-Circuit Protection: This prevents damage from sudden surges in current caused by faults.

Proper motor protection enhances reliability and extends the lifespan of electrical equipment. It also plays a critical role in maintaining operational efficiency while minimizing downtime. Without effective protection, even minor issues can escalate, leading to costly repairs or replacements.

Common Motor Circuit Faults

Motor circuits can face various faults during operation. Some of the most common include:

- Overload Conditions: This occurs when the motor operates beyond its rated capacity for too long.

- Short Circuits: They happen when there is unintentional contact between conductors, leading to sudden high current.

- Ground Faults: This involves a fault current flowing to the ground, potentially causing hazards.

Each of these faults can lead to serious motor damage. Identifying faults quickly is key to avoiding larger issues. Regular inspections and monitoring help to catch problems early.

Impact of Improper Protection

Failing to implement proper motor circuit protection can have severe consequences. Potential impacts include:

- Equipment Damage: Motors may burn out due to continuous overload or short circuit conditions.

- Safety Hazards: Short circuits can cause fires or electrical shocks, posing risks to both personnel and property.

- Operational Downtime: Unprotected motors may fail unexpectedly, leading to longer repair times and productivity loss.

Employing appropriate protection devices, such as overload relays and circuit breakers, minimizes these risks. Ensuring a robust protection strategy is vital to sustaining motor functionality and safety.

Overload Protection Fundamentals

Overload protection is essential for ensuring the safety and longevity of motors. It prevents damage caused by excessive current or heat. Understanding the causes, the role of overload relays, and how to select the right relay are all key components.

Causes and Effects of Overload

Overload conditions occur when a motor operates beyond its normal full-load current (FLC) for an extended period. This can be due to mechanical issues, incorrect sizing, or electrical faults. Common causes include:

- Mechanical Binding: Any physical obstruction can lead to increased load.

- Incorrect Sizing: A motor too small for its application may continuously run overloaded.

- Voltage Issues: Low voltage can cause motors to draw more current.

The effects of overload can be significant. Motors may overheat, leading to insulation failure or burnout. This not only damages the motor but can also create fire hazards or impact the entire system’s operation.

Role of Overload Relays

Overload relays are crucial devices that protect motors from overcurrent situations. They detect deviations from normal current levels and interrupt power when necessary. Key functions include:

- Monitoring: They continuously track motor current, ensuring it remains within safe limits.

- Tripping Mechanism: When overload conditions are detected, they disconnect the power supply.

- Reset Capability: After tripping, these devices can be reset manually or automatically, allowing for convenience in maintenance.

Effective use of overload relays can extend a motor’s service life and improve operational safety. They come in different types, including thermal and electronic relays, each with specific applications.

Thermal Overload Relay Selection

Choosing the right thermal overload relay is vital for effective motor protection. When selecting, consider these factors:

- Full-Load Current Rating: The relay must match the motor’s full-load current for accurate protection.

- Type of Motor: Different motors, like single-phase or three-phase, may require specific relays.

- Service Factor: Motors with a service factor above 1.0 can handle slight overloads. The relay should consider this when setting limits.

For instance, if a motor has an FLC of 24 amps, the thermal overload relay might be selected to allow up to 125% (30 amps) before tripping. Proper selection ensures reliable functionality and prevents unnecessary tripping during normal operations.

Short-Circuit Protection Techniques

Short-circuit protection is essential for the safety and efficiency of electrical systems. Understanding how to identify short-circuit faults and the appropriate devices to mitigate these risks is critical. This section explores short-circuit faults, the various types of circuit breakers available, and the importance of correct sizing and settings for effective protection.

Understanding Short Circuit Faults

A short circuit occurs when electrical current flows along an unintended path with low resistance. This situation can generate excessive current, leading to damage in wiring and equipment, and may even cause fires. Key indicators of short circuits include tripped breakers, blown fuses, and unusual heating of electrical components.

Identifying the cause of a short circuit is vital. Common reasons include faulty wiring, equipment failures, or damage from environmental factors. Operators should regularly inspect electrical systems, ensuring that all components are in good condition and properly insulated to prevent these faults.

Types of Circuit Breakers

Circuit breakers are crucial for protecting against short circuits. Two primary types are used: Miniature Circuit Breakers (MCBs) and Molded Case Circuit Breakers (MCCBs).

- MCBs are typically used for lower power applications. They automatically switch off the circuit when an overload or short circuit occurs.

- MCCBs handle larger loads and can be adjusted to trip at specific current levels. This adjustability is helpful for managing the needs of varying loads in industrial settings.

When selecting circuit breakers, factors such as the application’s voltage, current rating, and environment must be considered. Proper selection ensures effective protection against potential hazards.

Correct Sizing and Settings

Correct sizing of circuit breakers is vital for effective short-circuit protection. The size should correspond to the expected load and specific application requirements.

So the National Electrical Code (NEC) provides guidelines for sizing, ensuring that circuit breakers can handle short-circuit conditions while protecting against overloads. The following table summarizes standard practices:

| Device Type | Maximum Rating | Minimum Rating |

| MCB | Up to 100 A | Based on load currents |

| MCCB | 100 A to 1,200 A | Based on load requirements |

Additionally, settings, including time delays and trip current settings, should match the application needs. For instance, MCCBs may require coordination with other protective devices to prevent nuisance tripping. Properly sized and set protections minimize risks associated with short circuits and ensure reliable operation of electrical systems.

Motor Protection Devices and Their Applications

Motor protection devices play a critical role in protecting electric motors from faults and damage. These devices help ensure proper functioning and longevity of motor systems. Key considerations include selecting the right device, understanding application scenarios, integrating devices into control circuits, and maintaining equipment.

Device Selection Criteria

Choosing the correct motor protection device requires careful evaluation. Key factors include:

- Motor Type: Different motors, like induction or synchronous, may have specific protection needs.

- Current Rating: The device must match the motor’s full load current and starting current.

- Protection Features: Look for overload, short-circuit, and ground-fault features.

- Environmental Conditions: Devices must withstand temperature, humidity, and dust levels.

Common devices include overload relays, which protect against excessive current, and molded case circuit breakers (MCCB), offering robust protection against short circuits and overloads.

Application Scenarios for Different Devices

Different motor protection devices excel in specific applications:

- Overload Relays are ideal for applications with varying loads. They monitor motor current and trip when overloads occur, protecting the motor from heat damage.

- MCCBs are widely used in industrial settings to handle large motors. They provide flexible settings for current ratings and can handle short-circuit protection.

- Thermal Overload Relays are suited for smaller motors and applications where prolonged overload sensing is essential. These devices respond to heat generated by current flow.

- Circuit Breakers offer a dual function, combining overload protection with the ability to isolate circuits in emergencies.

Integration in Control Circuits

Integrating protection devices into control circuits enhances motor safety. Key elements of integration include:

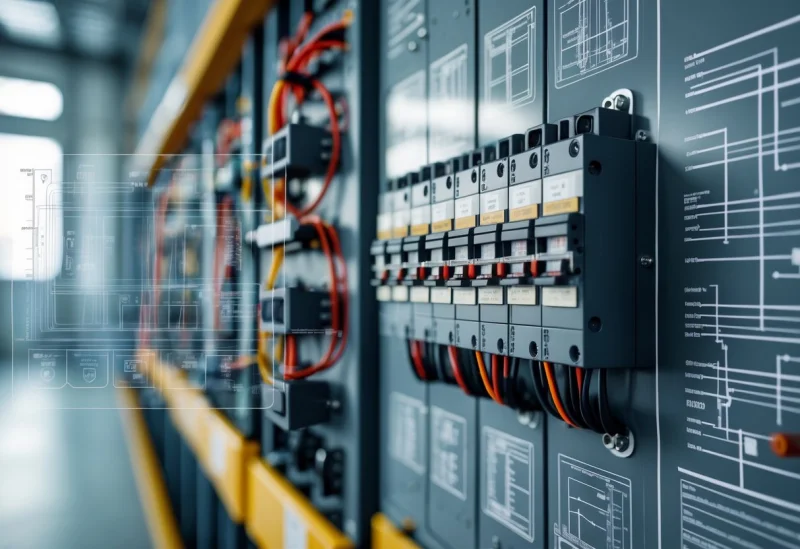

- Control Panels: Devices like overload relays and MCCBs are often mounted in control panels for easy access and monitoring.

- Interlocking Systems: Using auxiliary contacts in circuit breakers can prevent accidental restarts during maintenance.

- Feedback Systems: Implementing sensors that communicate with control equipment ensures that operators are notified of any issues.

- Automation: Many modern systems utilize programmable logic controllers (PLCs) to manage protections dynamically.

Correct integration maximizes efficiency and minimizes potential hazards.

Maintenance and Testing Best Practices

Regular maintenance and testing of motor protection devices are vital for reliable operation. Important practices include:

- Routine Inspections: Regularly check for signs of wear or overheating in protective devices.

- Testing: Conduct periodic testing to ensure devices are functioning properly. This can include testing trip functions and replacing worn-out components.

- Documentation: Keep accurate records of inspections and tests to track device performance over time.

- Training: Ensure that personnel are trained in handling protection devices and the specific requirements of each motor system.

Following these practices helps maintain device integrity, ensuring motor protection remains effective.

Advanced Protection Strategies and Modern Developments

Modern motor protection has evolved to address various risks and challenges in industrial settings. Advanced strategies include phase failure protection, ground fault solutions, and emerging smart technologies. These developments serve to enhance reliability and safety in motor operations.

Phase Failure and Single Phasing Protection

Phase failure or single phasing occurs when one phase of the electrical supply is lost. This can lead to motor overheating and damage. To prevent these issues, protection devices are installed to detect phase loss quickly.

Common protection methods include:

- Under-voltage relays: These disconnect the motor when voltage drops too low.

- Phase sequence relays: They ensure the correct phase rotation and disconnect the motor if the sequence is incorrect.

Implementing these devices preserves motor lifespan and efficiency.

Ground Fault and Earth Leakage Solutions

Ground faults happen when electricity escapes from the intended circuit, posing risks such as electrocution or fire. Earth leakage solutions detect small current flows to the ground, acting swiftly to cut off power.

Key protective devices include:

- Ground Fault Circuit Interrupters (GFCIs): These quickly shut down the circuit during a leakage.

- Residual Current Devices (RCDs): Designed to prevent electric shock, they monitor current balance and trip the circuit upon detecting imbalances.

These systems are critical for ensuring worker safety and protecting equipment.

Emerging Smart Protection Technologies

Smart protection technologies have emerged as essential tools in modern motor protection. These systems often use advanced sensors and data analytics to monitor motor conditions continuously.

Key features include:

- IoT connectivity: Allows real-time monitoring and alerts through mobile or web platforms.

- Predictive maintenance: Algorithms analyze data to predict failures before they occur, reducing downtime.

These innovations enhance traditional motor protection techniques, making them more effective and proactive in protecting assets.

Premium electrical and automation equipment

Gabby Electric is a trusted source for high-quality electrical and automation equipment. Their website, gabbyelectric.com, provides a wide range of products from well-known brands.

Product Offerings

- Motor Protection Circuit Breakers (MPCBs)

These devices protect motors from overcurrent and short circuits. They combine features of traditional overload relays with advanced isolation capabilities. - Automation Components

Gabby Electric offers various automation equipment, including sensors, control systems, and actuators that enhance operational efficiency in industrial settings. - Electrical Components

The site features essential electrical parts like circuit breakers, switches, and connectors. These items are crucial for safe and effective electrical distribution.

Key Features

- Competitive Prices

Customers can expect pricing that fits their budget without compromising quality. - Fast Delivery

Gabby Electric prioritizes quick shipping to minimize downtime for clients. - Online Ordering

The website offers a user-friendly interface for easy navigation and order placement.

Gabby Electric serves both the European Union and the United Kingdom. Their focus on quality and customer support makes them a notable player in the electrical supply market.

Ti potrebbe interessare:

Segui guruhitech su:

- Google News: bit.ly/gurugooglenews

- Telegram: t.me/guruhitech

- X (Twitter): x.com/guruhitech1

- Bluesky: bsky.app/profile/guruhitech.bsky.social

- GETTR: gettr.com/user/guruhitech

- Rumble: rumble.com/user/guruhitech

- VKontakte: vk.com/guruhitech

- MeWe: mewe.com/i/guruhitech

- Skype: live:.cid.d4cf3836b772da8a

- WhatsApp: bit.ly/whatsappguruhitech

Esprimi il tuo parere!

Che ne pensi di questa notizia? Lascia un commento nell’apposita sezione che trovi più in basso e se ti va, iscriviti alla newsletter.

Per qualsiasi domanda, informazione o assistenza nel mondo della tecnologia, puoi inviare una email all’indirizzo [email protected].

Scopri di più da GuruHiTech

Abbonati per ricevere gli ultimi articoli inviati alla tua e-mail.