Gasket Materials Explained: Choosing the Right Seal for Maximum Efficiency and Longevity

When it comes to maintaining the efficiency of commercial refrigeration systems, one small component plays a huge role — the gasket. It’s easy to overlook, yet it’s one of the most critical elements in ensuring a refrigerator or freezer operates smoothly and efficiently. The material used in manufacturing gaskets determines how well they perform under specific conditions, from temperature resistance to flexibility and lifespan.

Whether you manage a restaurant, grocery store, or industrial kitchen, understanding gasket materials helps you make better decisions about replacements and maintenance. Each type of material offers unique benefits, and choosing the wrong one can lead to premature wear or energy loss.

At Reliable Gaskets USA, we manufacture high-quality gaskets using a range of materials designed to meet the unique demands of every refrigeration system. Here’s everything you need to know about selecting the right one for your needs.

Why Material Matters in Gasket Performance

A gasket’s purpose is simple — to create an airtight seal that prevents cold air from escaping and warm air from entering. However, not all environments or appliances are the same. Freezers, coolers, and display cases experience different temperature fluctuations and moisture levels, which can affect how a gasket performs.

The type of material impacts:

- Durability: How long the gasket lasts before cracking or shrinking.

- Flexibility: The ability to maintain a tight seal over time.

- Temperature resistance: Performance under extreme cold or heat.

- Ease of maintenance: How easily the material can be cleaned and maintained.

Choosing the right gasket material ensures long-term efficiency, consistent temperature control, and reduced energy costs.

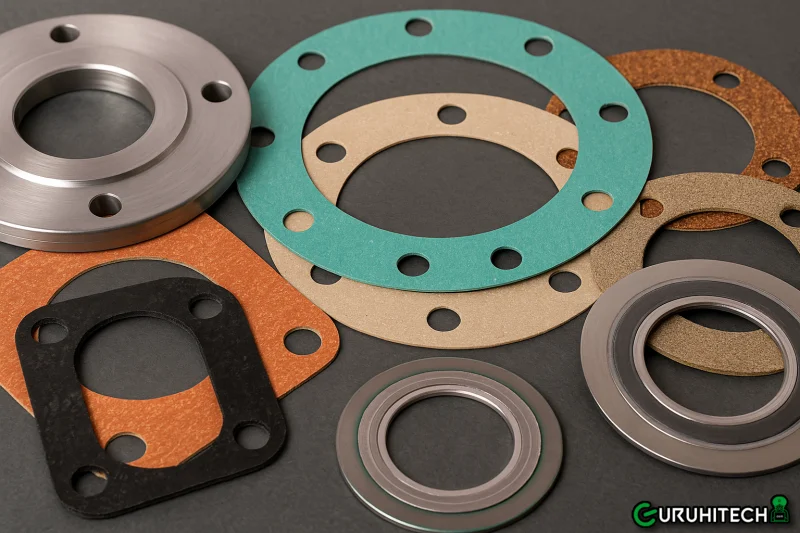

Common Materials Used in Gasket Manufacturing

There’s no one-size-fits-all when it comes to gaskets. Each material offers unique advantages, making it suitable for different types of refrigeration equipment.

1. PVC (Polyvinyl Chloride)

PVC is one of the most commonly used gasket materials due to its affordability and flexibility. It performs well in moderate temperature environments, such as standard commercial refrigerators.

Advantages:

- Cost-effective and easy to replace.

- Smooth, clean appearance ideal for food service equipment.

- Resistant to moisture and stains.

Considerations:

PVC can become brittle over time, especially in extremely cold environments. Regular maintenance is important to extend its lifespan.

2. Santoprene

Santoprene combines the flexibility of rubber with the durability of thermoplastics. It’s one of the most reliable options for both commercial and industrial refrigeration systems.

Advantages:

- Excellent resistance to temperature changes.

- Retains flexibility over time.

- Long-lasting and low-maintenance.

- Highly resistant to grease, chemicals, and UV exposure.

Best For:

High-traffic environments or systems exposed to frequent door openings, where durability is key.

3. Silicone

Silicone gaskets are known for their outstanding temperature tolerance, making them ideal for environments that experience both freezing and heating cycles.

Advantages:

- Withstands extreme temperatures (from -100°F to +400°F).

- Non-toxic and food-safe.

- Resistant to mold, bacteria, and odor absorption.

- Maintains elasticity for years.

Considerations:

Silicone gaskets can be more expensive but offer exceptional longevity and performance, making them a valuable investment for high-demand commercial kitchens.

4. EPDM (Ethylene Propylene Diene Monomer)

EPDM is another high-performance material commonly used in heavy-duty refrigeration systems. It offers great flexibility and excellent resistance to ozone, UV light, and temperature variations.

Advantages:

- Superior weather and oxidation resistance.

- Excellent sealing properties even at low temperatures.

- Affordable and easy to install.

Best For:

Outdoor units or environments with variable temperatures.

Factors to Consider When Choosing Gasket Materials

Selecting the right material requires understanding your equipment’s needs and working conditions. Here are key factors to evaluate before deciding:

- Operating Temperature Range:

Consider how cold or hot your equipment gets. Silicone performs best in extreme temperatures, while PVC works well for moderate ones. - Frequency of Use:

Constant door openings cause more wear on gaskets. In these cases, materials like Santoprene or EPDM provide better longevity. - Exposure to Chemicals or Grease:

Kitchens with heavy grease or chemical cleaners need materials that resist damage — Santoprene is a good choice here. - Budget and Longevity:

While lower-cost materials like PVC can save money upfront, investing in high-grade materials may reduce replacements over time.

Consulting with a professional manufacturer ensures your gasket material matches your appliance’s specific demands.

The Impact on Energy Efficiency

Gasket materials play a direct role in your refrigeration system’s energy performance. Poor sealing or premature material degradation can lead to significant energy waste.

A high-quality gasket reduces the load on compressors and cooling fans, allowing your appliance to maintain optimal temperature with less effort. This not only lowers energy consumption but also reduces maintenance costs and equipment downtime.

Replacing your gasket with the right material can cut energy usage by up to 15–20%, a noticeable saving over the long term for both commercial and residential applications.

Maintenance and Longevity Tips

Even the best gasket material needs care to perform its best. Here are some maintenance tips to maximize the lifespan of your gasket:

- Clean regularly: Wipe gaskets weekly with warm, soapy water to remove grime.

- Avoid harsh chemicals: Strong cleaners can break down the material.

- Inspect monthly: Look for cracks, warping, or loosened corners.

- Apply silicone lubricant: Keeps the gasket soft and prevents sticking.

- Check door alignment: Misaligned doors can compress or tear the gasket prematurely.

Following a simple maintenance routine ensures your gaskets stay functional and efficient for years.

Why Custom Gaskets Are Worth the Investment

While standard replacement gaskets are readily available, custom-manufactured gaskets provide superior performance. Custom designs ensure precise fits for your equipment model and operating conditions.

At Reliable Gaskets USA, we manufacture tailored gaskets to match exact dimensions and specifications. This precision fit enhances sealing performance, prevents air leakage, and ensures consistent cooling efficiency.

Whether you need replacement gaskets for walk-in coolers, freezers, or industrial units, our team delivers long-lasting solutions designed to meet your specific requirements.

Environmental Benefits of Durable Materials

Sustainable gasket materials contribute to both energy efficiency and waste reduction. Long-lasting seals mean fewer replacements and less material waste over time. Energy-efficient refrigeration also lowers greenhouse gas emissions by reducing overall electricity consumption.

Choosing the right gasket material is not just good for your business — it’s also good for the planet. Reliable, eco-conscious materials support green initiatives and long-term sustainability goals.

Why Choose Reliable Gaskets USA

When it comes to performance, precision, and durability, Reliable Gaskets USA is a trusted leader in gasket manufacturing and installation. Our expert team works with high-grade materials like silicone, Santoprene, and EPDM to ensure every gasket we produce meets the highest standards of quality.

We focus on delivering custom-fit solutions, quick turnaround times, and exceptional service. Our gaskets help businesses improve efficiency, save energy, and maintain optimal cooling performance year-round.

With Reliable Gaskets USA, you can count on durable products that enhance both performance and reliability.

Conclusion

Selecting the right gasket material is key to maintaining an efficient, long-lasting refrigeration system. Each material — from PVC to silicone — offers unique advantages depending on your operational environment and budget.

At Reliable Gaskets USA, we help clients identify and install the best gaskets for their specific needs. Our materials are tested for durability, performance, and energy efficiency, ensuring your equipment stays reliable for years to come.

When quality and longevity matter, choose Reliable Gaskets USA — where superior materials and expert craftsmanship seal the difference.

Ti potrebbe interessare:

Segui guruhitech su:

- Google News: bit.ly/gurugooglenews

- Telegram: t.me/guruhitech

- X (Twitter): x.com/guruhitech1

- Bluesky: bsky.app/profile/guruhitech.bsky.social

- GETTR: gettr.com/user/guruhitech

- Rumble: rumble.com/user/guruhitech

- VKontakte: vk.com/guruhitech

- MeWe: mewe.com/i/guruhitech

- Skype: live:.cid.d4cf3836b772da8a

- WhatsApp: bit.ly/whatsappguruhitech

Esprimi il tuo parere!

Ti è stato utile questo articolo? Lascia un commento nell’apposita sezione che trovi più in basso e se ti va, iscriviti alla newsletter.

Per qualsiasi domanda, informazione o assistenza nel mondo della tecnologia, puoi inviare una email all’indirizzo [email protected].

Scopri di più da GuruHiTech

Abbonati per ricevere gli ultimi articoli inviati alla tua e-mail.