Mass production challenges for smart device casings A complete guide to acrylic CNC machining

Introduction

Smart device manufacturers often encounter significant challenges during the prototype and low-volume production phases, particularly with engineering plastic enclosures. Issues such as warping, poor dimensional stability, and easily scratched surfaces can directly impede product testing and time-to-market schedules. These common pain points typically stem from an insufficient understanding of material properties, improper machining parameter settings, or a failure to optimize processing techniques for specific plastics like acrylic (PMMA) or ABS.

This article delves into how high-precision Plastic CNCmachining technology, specifically tailored for materials like acrylic, can effectively overcome these hurdles, enabling the rapid and high-quality manufacture of smart device housings. The following sections will provide a detailed, step-by-step analysis of the critical factors for success.

Why Acrylic is an Ideal Choice for Smart Device Prototype Enclosures?

MatWeb – Acrylic (PMMA) Properties(PMMA) is a premier choice for smart device prototype enclosures due to its unique property profile, balanced cost-effectiveness, and quality-assured supply chain, which together meet the rigorous demands of modern electronics development.

Superior Material Properties for Aesthetics and Function

Its exceptional combination of optical clarity, high strength, and excellent weather resistance directly fulfills the dual demands of premium appearance and reliable functionality. This makes it ideal for components like IoT sensor housings and display panels that must protect internal Smart device technologies while showcasing a high-quality finish.

A Balanced Choice Compared to Common Alternatives

When evaluated against other common prototyping plastics, acrylic offers a superior overall balance.

- Versus Polycarbonate (PC)

While PC boasts higher impact strength, it is generally more challenging and costly to machine, making acrylic a more efficient choice for Prototype manufacturing where extreme impact resistance is not the primary concern.

- Versus ABS Plastic

ABS, though easy to process and cost-effective, lacks the optical clarity and inherent UV resistance of acrylic. For applications requiring transparency and outdoor durability, Acrylic CNC machining is the compelling alternative.

Ensuring Quality Through Certified Sourcing

Procuring materials and services from a supplier with stringent certifications likeISO 9001 and AS9100D is crucial. This ensures material traceability and consistent quality from the outset, mitigating risks in the prototyping phase.

How Does High-Precision CNC Machining Overcome Acrylic’s Tendency to Crack or Melt?

The thermal sensitivity of acrylic is the primary challenge in its machining; excessive heat from incorrect cutting speeds or feed rates can lead to stress cracking or melting at the edges. Overcoming this requires a sophisticated approach that embodies High precision CNC machining. Professional machining service providers leverage optimized tool paths, such as climb milling, to reduce heat generation. They employ sharp, specialized cutters designed for plastics to ensure a clean shear rather than tearing the material.

Furthermore, effective cooling strategies, like precise air cooling, are critical to dissipate heat without introducing the stresses or surface clouding that liquid coolants might cause. These meticulous techniques ensure that the final CNC machining part has sharp edges and a high-quality surface finish, aligning with advanced Manufacturing innovation trends focused on zero-defect production. For detailed guidelines, authoritative resources like the Plastics Industry Association’s best practices for machining acrylic are invaluable references .

From Design to Part: What Does a Successful CNC Machining Process for a Smart Device Enclosure Look Like?

A successful journey from a digital model to a physical smart device enclosure involves a streamlined, multi-stage process that is central to effective rapid prototyping solutions. This workflow typically includes:

- 3D Model Design and DFM Analysis:

The process begins with a meticulous design review. Expert manufacturers provide Design for Manufacturability (DFM) feedback, suggesting optimizations to wall thickness, corner radii, and tolerances to prevent machining issues. - Programming and Toolpath Optimization:

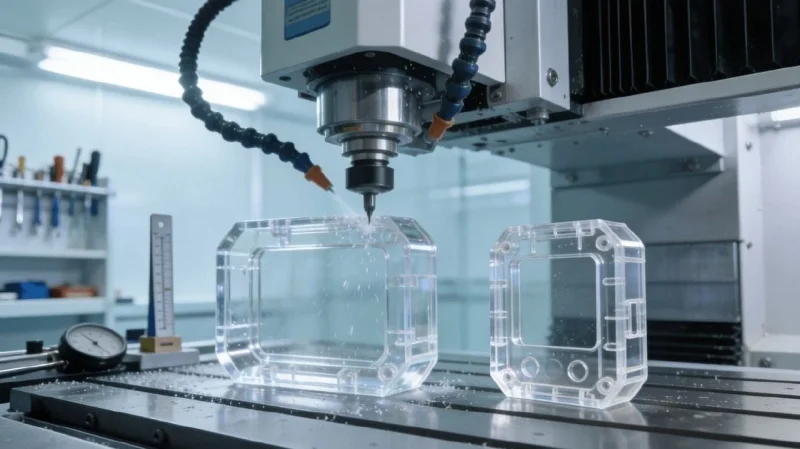

Engineers program the CNC machines with optimal toolpaths, selecting the most appropriate cutters and strategies for acrylic to minimize stress and heat. - Precision Machining:

The part is machined on advanced, often multi-axis, CNC equipment using rigorously controlled parameters specifically developed for acrylic. - Quality Control:

Critical dimensions are verified using precision measurement tools like coordinate measuring machines (CMM) to ensure they meet all specified tolerances. - Surface Finishing:

A range of post-processing options, from mechanical polishing to sandblasting for a matte finish, can be applied to achieve the desired aesthetic and functional properties.

Understanding the factors that influence the CNC machining price is essential for budgeting. Key elements include the volume of material used, the complexity of the geometry (impacting machining time), the required tolerances, and the chosen surface finish. For a more in-depth look at material-specific processing, a dedicated resource is available: for an extensive exploration of acrylic material, refer to this professional article on Plastic CNCmachining services .

Besides Acrylic, What Other Engineering Plastics are Suitable for CNC Machining Smart Devices?

While acrylic is ideal for transparent applications, numerous other engineering plastics serve distinct purposes in smart devices. ABS CNC machining is widely used for opaque housings and internal brackets due to the material’s high toughness and ease of post-processing, such as painting and bonding. Nylon CNC machining is excellent for components requiring high mechanical strength, wear resistance, and durability, making it suitable for gears, connectors, and structural parts.

Poly oxy methylene (POM), known for its superb dimensional stability and low friction, is often chosen for precision components like gears and sliding elements. The selection of the right Engineering Plastics depends on a careful evaluation of the application’s requirements for strength, temperature resistance, chemical resistance, and cost.

Material Key Advantages Typical Smart Device Applications Acrylic (PMMA)

High transparency, good strength, UV resistance Display covers, light guides, transparent housings ABS High impact strength, good toughness, easy to finish Opaque device housings, internal structural components Nylon (PA) High mechanical strength, excellent wear resistance Gears, connectors, snap-fits, durable structural parts H2: How to Choose a Partner to Ensure Prototyping Success and Scalability?

Selecting the right manufacturing partner is critical to the success of CNC prototyping services and a smooth transition to mass production. The ideal partner should demonstrate robust technical capabilities, including advanced multi-axis CNC equipment and expertise in machining a wide range of materials.

A certified quality management system, such as IATF 16949 for automotive-grade components or AS9100D for aerospace, is a strong indicator of a commitment to consistent quality. Environmental management standards like ISO 14001 are also increasingly important. Perhaps most crucially, the partner should offer comprehensive engineering support, providing expert DFM Prototype manufacturing feedback to optimize designs for cost, performance, and manufacturability from the very beginning.

A partner that can scale from prototype to high-volume production offers significant long-term advantages. To learn more about seamless transition from prototyping to mass production services, you can visit the professional high precision CNCmachining. A supplier that embodies these qualifications, such as JS Precision, with its deep expertise in precision manufacturing, can provide full-spectrum support from concept to final production.

Conclusion

In summary, a deep understanding of the properties of acrylic and other engineering plastics, combined with high-precision CNC machining technology and a rigorous process, allows smart device manufacturers to effectively overcome common prototype enclosure defects. This approach significantly enhances development efficiency and product quality, laying a solid foundation for large-scale production.

If you are facing manufacturing challenges with your smart device enclosures, contacting a professional precision manufacturing service provider for a free DFM analysis and an instant quote is a recommended step towards bringing your ideas to precise reality.

Author Bio

This article was authored with technical support from an expert with over a decade of experience in the precision manufacturing field, specializing in providing innovative prototyping and production solutions for the technology industry.

H2:FAQs

Q1: How high of a transparency can be achieved with CNC machined acrylic parts?

A1: Professional CNC machining and subsequent polishing can achieve near-optical clarity. The key lies in using appropriate cutting parameters and cooling to avoid surface clouding, followed by flame or mechanical polishing to restore smoothness.

Q2: What are the main advantages of CNC machining acrylic enclosures compared to 3D printing?

A2: CNC machined acrylic parts generally offer superior structural strength and sealing compared to 3D printed parts. CNC produces fully dense components without layer lines, resulting in better mechanical properties and higher dimensional stability, making them ideal for functional prototypes and end-use products.

Q3: Is CNC machining economical for small-batch production of plastic enclosures?

A3: For small batches (from tens to hundreds of units), CNC machining is typically very economical. It avoids the high cost of injection molds and offers flexibility for design iterations. CNC is the ideal choice for prototyping and small-lot production.

Q4: How can you prevent thin-walled structures from breaking during CNC machining of acrylic?

A4: Machining thin-walled structures requires a multi-faceted approach: using sharp, single-flute spiral cutters to reduce cutting force; employing high spindle speeds with slow feed rates; and applying a multi-step cutting strategy to avoid stress concentration. Experienced programming and appropriate fixturing are also crucial.

Q5: What surface treatments are available for CNC machined acrylic parts?

A5: Beyond high-gloss polishing, common surface treatments for acrylic include silk-screen printing, sandblasting (for a matte effect), vacuum metallizing (for a metallic look), and even UV spraying. The surface of acrylic is also easy to bond, facilitating subsequent assembly.

Scopri di più da GuruHiTech

Abbonati per ricevere gli ultimi articoli inviati alla tua e-mail.