Understanding the Role of Fixture Inspection for Quality Control

Introduction to Checking Fixtures

Quality control in manufacturing is vitally important to ensuring products conform to specific standards and specifications, with checking fixtures playing an essential part in maintaining precision and consistency. Checking fixtures allow manufacturers to rapidly verify dimensions, angles, tolerances, etc. — that’s where checking fixtures come into play! Not only can these devices facilitate quality assurance efforts efficiently but they can also significantly decrease errors that lead to costly reworks or product failure.

As a manufacturer of checking fixtures, understanding their importance can greatly increase production line efficiency. In this blog post we cover what checking fixtures are, their benefits, different types available to manufacturers and practical tips on using them for superior quality control. Whether new to this concept or looking to enhance existing processes there’s something here for everyone involved with manufacturing excellence! Join us as we examine these tools that have an enormous effect on product quality and overall operational success!

Benefits of Using Checking Fixtures in Quality Control

Checking fixtures play an integral part in improving quality control processes across industries, helping ensure parts and components meet specific specifications with reduced risks of defects.

One significant advantage is increased accuracy. Employing checking fixtures allows manufacturers to consistently verify dimensions and tolerances without human error being introduced into inspection procedures. This leads to reduced human errors during inspection processes.

Another key benefit is efficiency: these tools streamline inspection processes for faster production line turnaround times; less time spent measuring means more focus on output.

Notable cost savings also stem from early identification of defects with checking fixtures – early spotting can prevent costly rework or returns later in the manufacturing cycle, saving both time and money in terms of time savings alone.

Also, they foster standardization across different teams and shifts for quality checks to ensure uniform product quality regardless of who conducts inspections.

Types of Checking Fixtures

Checking fixtures are available in various forms to meet various quality control needs. Here we explore some of the more frequently used fixtures.

First is an assembly checking fixture, designed to verify that components fit together securely during manufacturing processes and detect potential alignment issues early.

Next is the functional testing fixture, used to verify whether a product operates as intended – something particularly valuable in industries where precision is key, like automotive or aerospace manufacturing.

Inspection gauges are another popular variation used for quickly measuring dimensions and tolerances quickly and efficiently. Often simpler tools used, inspection gauges offer quick measurements for dimensions and tolerances with efficiency and speed.

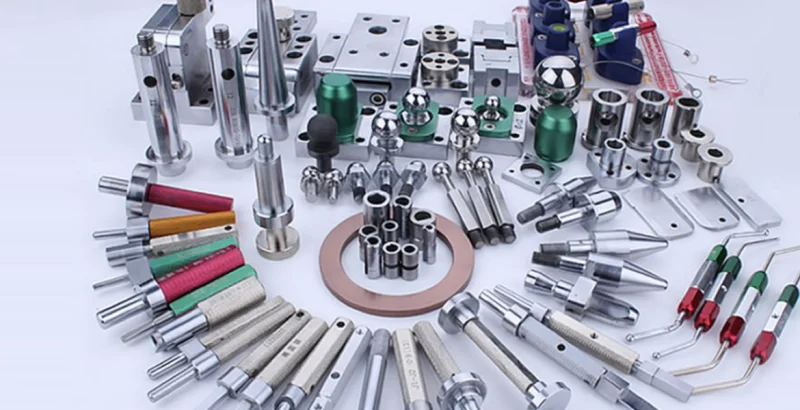

At Favamill, we design custom fixtures tailored for specific products or components to improve accuracy by meeting individual design or material challenges. Each type plays its part in maintaining high-quality standards across various industries.

Components of a Quality Checking Fixture

Quality check fixtures consist of several key components designed to guarantee accuracy and efficiency in production.

At first, the base or platform provides stability; it ensures all elements remain securely placed during inspections to eliminate unnecessary movement that might lead to errors and avoid misinterpretations of results.

Locating pins and supports provide precise alignment for products in their fixture. Their design must accommodate different shapes while guaranteeing consistent positioning over time.

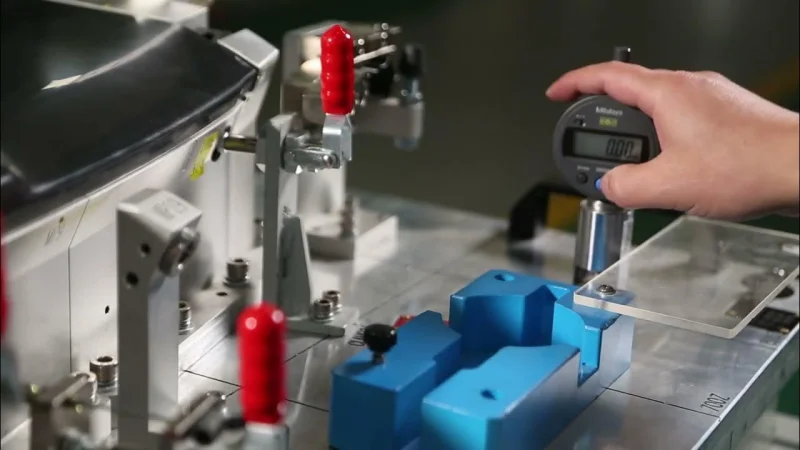

Integration of measuring devices such as gauges or sensors into fixtures provides real-time measurements that enable operators to easily spot defects quickly.

Adjustability is of utmost importance in fixtures. Many include features which enable quick modifications based on different products or specifications without extensive recalibration efforts.

Together, these components come together to form an efficient tool that streamlines quality control processes across diverse manufacturing industries.

How to Implement Checking Fixture Quality Control Arrangement

Utilizing a checking fixture in quality control requires minimal steps but requires precise execution. First ensure the fixture is both clean and calibrated – this sets up for accurate measurements.

Carefully place the part or assembly into its fixture without forcing it. Accurate alignment is critical to delivering reliable results.

As soon as your equipment and procedures are in order, conduct checks according to established procedures and document all findings carefully for traceability and future use.

After testing has concluded, carefully examine both the component being examined as well as its testing fixture for any wear or damage, since proper care and maintenance will prolong its longevity and accuracy when testing components and devices.

Bear in mind that sharing information about every step with your team improves understanding and efficiency throughout the process, engaging everyone can result in improved practices overall.

Common Mistakes to Avoid When Using Checking Fixtures

One major mistake involves failing to calibrate checking fixtures regularly – regular maintenance ensures accuracy while failing to calibrate puts you at risk of accepting defective products.

Misuse of fixtures to secure measurements or ensure verification can also lead to complications, with each component needing its own set up for accurate verification and measurement.

Skipping operator training can create serious complications. Employees need to know how to utilize checking fixtures efficiently for maximum effectiveness.

Additionally, teams may overlook documenting. By keeping detailed records over time and tracking performance trends closely, keeping an overview is invaluable in monitoring progress and spotting future potential problems.

Failing to evaluate wear and tear on fixtures can have serious repercussions. Regular inspections are vital in order to preserve optimal function and avoid costly errors later down the line.

Best Practices for Maintaining and Calibrating Checking Fixtures

Preserving and calibrating checking fixtures are an integral component of quality control processes, helping ensure accuracy during quality analysis processes. Regular checks can identify wear or damage that might otherwise lead to errors – thus helping mitigate against mistakes altogether.

Begin with an ongoing cleaning schedule. Dust and debris can obstruct measurements, so keeping the fixture tidy is of vital importance. Be sure to use appropriate cleaners that won’t scratch surfaces when cleaning them off.

Calibration should occur periodically or following significant use. Use precision tools to verify measurements against established standards to ensure your fixtures consistently deliver reliable results. This way you ensure their reliability will never change over time.

Documenting maintenance practices is vital. Keep a thorough record of calibrations and repairs completed to effectively track performance over time.

Establish and train staff in correct handling techniques in order to minimize wear-and-tear during usage of fixtures, prolong their longevity while improving production efficiency. Training your team also will extend fixture longevity.

Case Studies: Real World Examples of How Fixture Checking Improved Quality Control

One major automotive manufacturer faced challenges with component dimensions. Quality control was inconsistent and delays and additional costs increased significantly; by installing checking fixtures specifically tailored for their components they achieved great improvements during assembly processes; precise measurements allowed precise assembly processes so every part met stringent specifications.

Medical device company struggled with product reliability. To address it, they installed modular checking fixtures into their production line to quickly identify defects during manufacture – significantly cutting waste reduction efforts and saving resources in the process.

An electronics firm took advantage of custom checking fixtures designed specifically to inspect circuit board assemblies, finding that these tools helped streamline inspection processes while increasing throughput by 30%.

These case studies showcase how tailor-made solutions can elevate quality control across various industries. Each instance emphasizes how investing in effective checking fixtures has transformed operational efficiencies and product integrity.

Conclusion

Checking fixtures are invaluable tools for manufacturers seeking to streamline production processes and meet stringent quality standards. They not only streamlinine operational procedures but also guarantee they meet strict specifications.

Regular maintenance and calibration extend the lifetime of these tools because they play an essential part in streamlining operational procedures while assuring customers their product complies with this criteria.

Businesses will discover many advantages to adopting automation: increased accuracy, lower waste levels and overall increased productivity. Businesses may select from either manual or automated options depending on what best fits their requirements.

Ti potrebbe interessare:

Segui guruhitech su:

- Google News: bit.ly/gurugooglenews

- Telegram: t.me/guruhitech

- X (Twitter): x.com/guruhitech1

- Bluesky: bsky.app/profile/guruhitech.bsky.social

- GETTR: gettr.com/user/guruhitech

- Rumble: rumble.com/user/guruhitech

- VKontakte: vk.com/guruhitech

- MeWe: mewe.com/i/guruhitech

- Skype: live:.cid.d4cf3836b772da8a

- WhatsApp: bit.ly/whatsappguruhitech

Esprimi il tuo parere!

Che ne pensi di questa notizia? Lascia un commento nell’apposita sezione che trovi più in basso e se ti va, iscriviti alla newsletter.

Per qualsiasi domanda, informazione o assistenza nel mondo della tecnologia, puoi inviare una email all’indirizzo [email protected].

Scopri di più da GuruHiTech

Abbonati per ricevere gli ultimi articoli inviati alla tua e-mail.