Which Materials Work Best with Handheld Laser Welding Systems?

Choosing the right material is just as critical as mastering your welding technique. Even the most advanced hand held laser welder will struggle if the metal reflects too much light, conducts heat too quickly, or cracks under stress. Understanding which materials perform best ensures precise, durable welds and maximizes your investment in this transformative technology.

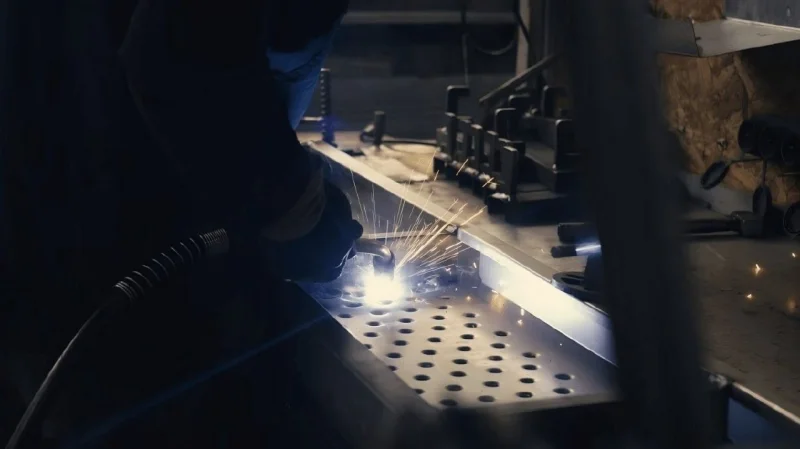

Handheld laser systems bring portability, precision, and minimal heat-affected zones to fabrication and repair work. They’re fast becoming the preferred tool for manufacturers, fabricators, and maintenance professionals worldwide. In this guide, you’ll learn which metals deliver the best results, what challenges to expect, and how to fine-tune parameters for success.

Material Properties That Influence Laser Weldability

Before striking an arc—or in this case, focusing a beam—you need to know how materials behave under laser energy.

Key factors include:

- Reflectivity & Absorption: Highly reflective metals like copper and gold reflect most laser energy, demanding higher power or different wavelengths.

- Thermal Conductivity: Materials that dissipate heat quickly require more energy to form a proper weld pool.

- Melting Point & Specific Heat: Higher melting points need greater intensity; lower points require fine control to prevent burn-through.

- Oxidation Behavior: Surface oxides can scatter or absorb energy unevenly—cleaning the surface is essential.

- Crack Sensitivity & Alloy Composition: Elements such as carbon, sulfur, and phosphorus can create brittleness if not managed correctly.

Understanding these fundamentals allows you to tailor settings—laser power, speed, focus, and shielding gas—for optimal results.

Metals Well Suited for Handheld Laser Welding

Stainless Steel

Stainless steel is one of the easiest and most reliable materials for laser welding. Grades such as 304, 316, 321, 410, and 430 offer strong absorption and moderate thermal conductivity, enabling smooth, consistent welds. A hand held laser welder handles these grades effortlessly, producing clean seams with minimal distortion.

Tips:

- Use argon or nitrogen shielding gas.

- Clean surfaces thoroughly to avoid oxide contamination.

- Maintain moderate power to prevent excessive penetration.

Carbon Steel & Low-Alloy Steels

Mild and low-carbon steels respond well under controlled conditions. Medium- and high-carbon steels, however, need slower speeds or preheating to prevent cracking from rapid cooling.

Best Practice: Adjust travel speed and preheat slightly when dealing with thicker or high-carbon sections to reduce stress.

Aluminum & Aluminum Alloys

Aluminum presents both opportunities and challenges: high thermal conductivity and reflectivity require careful tuning. Alloys such as 1050, 3003, 4047, and 6061 can yield excellent results when parameters are optimized. Continuous-wave laser mode often produces better penetration.

Key Considerations:

- Increase power or reduce speed to compensate for heat loss.

- Use proper shielding gas to prevent oxidation.

- Ensure joints are free from oil or oxide films.

Titanium & Titanium Alloys

Titanium is highly compatible with laser welding. It absorbs laser energy efficiently and forms strong, corrosion-resistant joints when adequately shielded with inert gas to avoid oxidation.

Nickel & Nickel-Based Alloys

Inconel, Hastelloy, and Monel respond well to laser energy, provided surfaces are clean and parameters are carefully controlled. These materials are common in aerospace and chemical applications where high-temperature performance is crucial.

Copper & Copper Alloys / Brass / Bronze

Copper’s reflectivity and thermal conductivity make it challenging—but not impossible. Modern systems use higher-power or green-wavelength lasers to improve absorption.

Die / Tool Steels

Used frequently for mold repair, tool steels can be welded successfully with a hand held laser welder when heat input is tightly controlled. Low-power, pulsed modes help prevent micro-cracking and preserve tool hardness.

Materials That Are Difficult or Less Suited

Not every material is ideal for handheld laser welding. Highly reflective or exotic metals like silver and gold typically need specialized wavelengths. Some aluminum or copper alloys with high silicon content can produce porosity or cracking.

Non-metallic materials—plastics, ceramics, or composites—generally require entirely different laser bonding technologies and are not suited to portable welding systems.

Thickness, Penetration & Power Considerations

Most handheld laser welders are optimized for thin to medium thicknesses.

| Material | Typical Thickness Range | Notes |

| Stainless Steel | up to ≈10 mm | Strong results with minimal distortion |

| Carbon Steel | 6 – 8 mm | Preheat thick sections |

| Aluminum | 3 – 6 mm | Requires higher power due to heat loss |

| Copper | ≤3 mm | High reflectivity, lower penetration |

Best Practices:

- Balance power and travel speed—too fast yields incomplete fusion, too slow overheats the joint.

- Maintain proper focus distance to concentrate energy.

- Use pulse or modulated modes for delicate or thin materials.

Best Practices & Techniques for Handheld Laser Welding

Achieving consistent, high-quality welds involves a disciplined approach:

- Clean the Surface – Remove rust, grease, and oxide layers; laser welding demands spotless joints.

- Use Proper Shielding Gas – Argon or helium prevents oxidation and stabilizes the weld pool.

- Optimize Beam Parameters – Adjust focus, power, and pulse settings to the metal type and thickness.

- Control Travel Speed – Match speed with energy input for smooth fusion without burn-through.

- Consider Preheating – Especially for thick or high-carbon steels to reduce stress gradients.

- Adopt the Right Technique – Maintain consistent torch angle and distance for uniform penetration.

- For Copper and Reflective Alloys – Green or blue lasers enhance absorption and reduce defects.

With experience, you’ll find that even challenging alloys become manageable when these principles guide your workflow.

Emerging Trends in Handheld Laser Technology

Advancements are making hand held laser welders more powerful, precise, and user-friendly:

- AI-Assisted Control: Real-time feedback systems automatically fine-tune beam power and travel speed.

- Compact Fiber Lasers: Lightweight sources improve portability without sacrificing performance.

- Integrated Safety Sensors: Automatic shutoff systems and temperature monitoring enhance operator safety.

- Energy Efficiency Upgrades: New fiber lasers deliver higher output with lower power consumption.

These developments mean that welding processes once confined to factories are now achievable in small workshops and field settings with professional-grade results.

Precision in Your Hands

When it comes to reliability and performance, Denaliweld stands out as a trusted name in portable welding innovation. Its hand held laser welder solutions combine advanced optics, ergonomic design, and intuitive controls to deliver consistent, high-quality welds on a wide range of materials.

From stainless steel fabrication to aluminum repair, their systems are engineered to maximize speed and accuracy while minimizing distortion and cleanup. Designed for both professionals and newcomers, they make cutting-edge laser welding accessible, efficient, and sustainable.

Conclusion

Many metals—stainless steel, carbon steel, aluminum, titanium, and nickel—perform exceptionally well with handheld laser systems when parameters are properly tuned. Materials such as copper or brass require more care but can still yield excellent results using the right techniques and wavelengths.

By understanding how each material interacts with laser energy, you can harness the full potential of your hand held laser welder to achieve cleaner seams, stronger bonds, and faster production cycles. Partnering with experts ensures that your equipment and knowledge evolve together—empowering you to weld with precision anywhere, anytime.

Ti potrebbe interessare:

Segui guruhitech su:

- Google News: bit.ly/gurugooglenews

- Telegram: t.me/guruhitech

- X (Twitter): x.com/guruhitech1

- Bluesky: bsky.app/profile/guruhitech.bsky.social

- GETTR: gettr.com/user/guruhitech

- Rumble: rumble.com/user/guruhitech

- VKontakte: vk.com/guruhitech

- MeWe: mewe.com/i/guruhitech

- Skype: live:.cid.d4cf3836b772da8a

- WhatsApp: bit.ly/whatsappguruhitech

Esprimi il tuo parere!

Ti è stato utile questo articolo? Lascia un commento nell’apposita sezione che trovi più in basso e se ti va, iscriviti alla newsletter.

Per qualsiasi domanda, informazione o assistenza nel mondo della tecnologia, puoi inviare una email all’indirizzo [email protected].

Scopri di più da GuruHiTech

Abbonati per ricevere gli ultimi articoli inviati alla tua e-mail.