Best Handheld Laser Welding Machines for Small Workshops (2026 Guide)

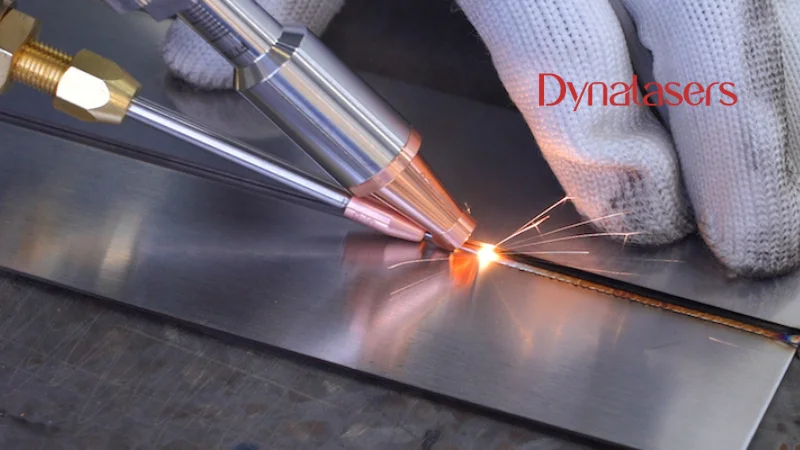

Handheld laser welding is becoming increasingly popular in small processing environments because these places usually place greater emphasis on flexibility, efficiency and space utilization. Compared with traditional welding methods, handheld laser welders achieve a good balance between welding accuracy, speed and operation control, and are well-suited for small factories that need to handle various processing tasks.

This article will compare the differences between laser welding and traditional welding methods, recommend the best handheld laser welding device, explain how it meets the actual needs of small workshops in 2026, and discuss the conveniences it brings in daily operations.

What Makes Handheld Laser Welding Different

Unlike traditional MIG and TIG welding methods, laser welding employs a highly focused energy source. When using the highest quality fiber laser welder, the heat is precisely transferred to the welding area rather than being dispersed over a larger area.

This localized heat input allows metal to melt and solidify rapidly, resulting in:

- Narrow, consistent weld seams

- Minimal thermal distortion

- Reduced surface oxidation

- Cleaner joints with less post-weld finishing

For materials such as stainless steel and aluminum, this difference becomes more pronounced in terms of the appearance of the welds and the accuracy of the dimensions.

Materials Commonly Processed

Handheld fiber laser welders are widely used for joining:

- Stainless steel components

- Carbon steel parts

- Aluminum sheets and profiles

- Copper and brass elements

- Standard industrial alloys

Because of their flexible functions, they are very suitable for workshops where various materials need to be welded on a daily basis.

Typical Use Scenarios in Small-Scale Fabrication

Because of their portability and ease of control, handheld laser welders are often found in:

- Furniture and kitchen equipment fabrication

- Light automotive repair and component welding

- On-site structural maintenance

- Door and window frame assembly

- Mold repair and precision part rework

In an environment that places greater emphasis on operation speed and stability, handheld systems can achieve a good balance between controllability and efficiency without relying on complex large-scale automation.

Why Dynalasers Fiber Laser Welders Fit the Needs of Small Workshops

Dynalasers handheld laser welders are designed to support the real operating conditions of small workshops, combining precise weld control with flexible handling and reliable performance for routine fabrication work.

1. Dynalasers M Series

- Customizable power levels up to 1800W for different industries

- Perfect balance between flexibility and industrial capability

2. Dynalasers D Series

- Deep penetration capability, up to 7mm

- Combines laser equipment, welding gun, wire feeders and gas cylinders together

3. Dynalasers S Series

- Ultra-lightweight design (S10 as light as 8 kg)

- Ideal for mobile repairs, tight spaces, and rapid material changes

Key Advantages

- One piece of equipment can perform welding, cleaning and cutting. It can handle multiple tasks without the need to switch between different machines.

- Self-developed laser source, with stable output, providing greater peace of mind when used.

- Air-cooled design, with low requirements for the environment. It can operate normally in both hot and cold weather (-15°C to 40°C).

- The welding effect is concentrated and stable, and the weld strength and consistency are better.

- Offer a two-year warranty and have a professional technical support team available.

Dynalasers has provided a set of efficient and cost-effective welding solutions for small factories. It not only significantly reduces daily operating costs but also maximizes welding performance within limited space and budget.

Operational Benefits of Handheld Laser Welding in Small Workshops

The handheld laser welding system is quite different from traditional welding equipment in terms of actual operation. It can help small factories better address daily production issues such as efficiency, consistency, and space constraints.

Key Advantages

1. Rapid Welding Speed

Laser welding is typically 2–3 times faster than TIG, enabling shops to finish jobs quickly and improve turnover.

2. Minimal Post-Processing

Clean weld seams often eliminate grinding or polishing, cutting manual labor time significantly.

3. Reduced Energy Consumption

Studies show up to 30–50 percent lower energy usage compared with arc welding equipment.

4. Easy Learning Curve

Operators can achieve consistent welds after only a short training session, making it ideal for small teams.

5. Multi-Function Capability

Many handheld machines include additional modes for cutting, cleaning, or wire feeding—expanding a shop’s operational range.

6. Space-Saving Operation

Compact, integrated machines fit easily into crowded workshops where every square meter matters.

These advantages not only enhance production efficiency but also reduce operational pressure. This is precisely why many small metal processing enterprises choose handheld laser welding machines as their primary welding tools.

Practical Considerations for Small Workshops

Although handheld laser welding equipment has many advantages, there are also some aspects that need to be considered in advance when using it. Small factories should assess thoroughly before making a purchase.

Potential Drawbacks

- Higher upfront cost than TIG or MIG systems.

- Requires attention to laser safety protocols (Class 4 laser).

- Reflective materials like aluminum and copper may require parameter optimization.

- Some consumables—such as protective lenses—require periodic replacement.

- Lower equipment utilization may delay ROI if workload is inconsistent.

However, for workshops with relatively stable welding demands, over time, the savings in labor costs, energy consumption, rework times, and overall efficiency improvements often outweigh and even exceed the initial investment in equipment.

ROI of Handheld Laser Welding Machines

After selecting the appropriate portable laser welding equipment, many workshops can typically recover their investment within one to two years and achieve a real cost return.

ROI Drivers

- Faster production

- Reduced grinding and post-processing

- Lower energy consumption

- Minimal equipment maintenance

- Shorter training time

- Reduced material distortion and scrap

Comparison Snapshot

| Aspect | Conventional Welding | Handheld Laser Welding |

| Speed | Slow | Fast |

| Precision | Moderate | High |

| Heat Distortion | Significant | Minimal |

| Energy Use | High | Low |

| Maintenance | Frequent | Minimal |

| Learning Curve | Moderate | Easy |

| Typical ROI | 5–6 years | 1–3 years |

For those businesses that both aim to ensure welding quality and strive to enhance production efficiency, handheld laser welders have demonstrated an extremely high return on investment in the current metal processing industry.

Key Factors in Selecting a Handheld Laser Welder for Small Workshops

When choosing a handheld laser welding machine, merely focusing on the power output is not sufficient. There are many technical and operational factors that can affect the actual performance.

1. Power Output

Compact welders typically range from 800 W to 1800 W.

- Lower power (800–1200 W): Thin metals, precision jobs

- Higher power (1500–1800 W): Thicker materials and faster throughput

2. Cooling System

The air-cooling system is highly suitable for use in workshops as it does not require additional configurations such as coolers, filters or water treatment equipment, making it more convenient to operate.

3. Portability

The lightweight design makes the operation process more convenient and also facilitates the movement of operators between different workstations.

4. Multi-Function Integration

It integrates welding, cutting, cleaning and wire feeding functions, enabling the completion of more tasks with fewer equipment.

5. Reliability & Warranty

A comprehensive after-sales service can ensure the long-term stable operation of the equipment and also reduce the impact of downtime. High-end brands usually offer longer warranty periods and more prompt technical support. For example, Dynalasers provides long-term warranty services.

Safety Requirements in Handheld Laser Welding Applications

In actual workshop usage, handheld laser welding systems need to be equipped with clear and reliable safety measures to ensure the stable operation of the equipment and to protect the safety of the operators.

- Use of certified laser protective eyewear

- Adequate ventilation or fume extraction

- Controlled access to trained operators

- Regular inspection of optics and cables

- Proper shielding gas flow and beam alignment

Consistent safety practices not only protect operators but also extend equipment lifespan.

Frequently Asked Questions (FAQs)

1. Can a handheld laser welder fully replace TIG or MIG in small workshops?

For thin to medium-thickness metals, yes. Laser welders provide faster, cleaner, and more accurate results with less post-processing.

2. Is it difficult for beginners to learn laser welding?

It depends on your device. The laser welding device of Dynalasers features an intuitive operation interface and preset welding modes. Most operators can master it proficiently after a brief training session.

3. Are handheld systems suitable for outdoor and mobile repairs?

Yes. Lightweight, air-cooled models such as Dynalasers handheld laser welders are ideal for field operations.

4. How important is machine weight for daily welding work?

Very important. Lighter welding guns reduce fatigue and improve control during long shifts.

5. What materials can Dynalasers handheld machines weld?

They support stainless steel, carbon steel, aluminum, copper, brass, and many alloys.

Final Thoughts

In actual workshop usage, especially as handheld laser welding systems become more widely adopted in 2026, clear and reliable safety measures are essential to ensure stable equipment operation while effectively protecting operator safety.

The Dynalasers smart laser welding machine provides portable and industrial laser welding solutions designed to meet the practical needs of small manufacturing environments. Workshops seeking tailored laser welding configurations and technical clarification may obtain further information by consulting with Dynalasers’ technical team.

Ti potrebbe interessare:

Segui guruhitech su:

- Google News: bit.ly/gurugooglenews

- Telegram: t.me/guruhitech

- X (Twitter): x.com/guruhitech1

- Bluesky: bsky.app/profile/guruhitech.bsky.social

- GETTR: gettr.com/user/guruhitech

- Rumble: rumble.com/user/guruhitech

- VKontakte: vk.com/guruhitech

- MeWe: mewe.com/i/guruhitech

- Skype: live:.cid.d4cf3836b772da8a

- WhatsApp: bit.ly/whatsappguruhitech

Esprimi il tuo parere!

Ti è stato utile questo articolo? Lascia un commento nell’apposita sezione che trovi più in basso e se ti va, iscriviti alla newsletter.

Per qualsiasi domanda, informazione o assistenza nel mondo della tecnologia, puoi inviare una email all’indirizzo [email protected].

Scopri di più da GuruHiTech

Abbonati per ricevere gli ultimi articoli inviati alla tua e-mail.