CNC Programming Tips to Maximize Efficiency and Accuracy

Introduction

CNC programming is the core in modern prototyp manufacturing. With efficiency and precision as the top priorities mastering this art will elevate your machining capabilities to new levels. If you’re an experienced professional or just beginning out knowing how to make use of CNC programmers is vital to maximize resource and time.

Imagine turning the raw material into complex designs, with the least amount of waste and with maximum precision. That’s the power of CNC programming! As industries change and the need for top-quality parts increases making fine-tuning your method essential. This blog article will give you helpful tips that will can not only help you improve your capabilities but also assist you avoid common mistakes in the field of CNC machines.

Are you ready to increase efficiency? Let’s explore the fundamentals to CNC programming!

Understanding CNC Programming

CNC programming is the process of instructing computers to accomplish precise tasks. It transforms the specifications of the design into a language CNC machines can comprehend which ensures precision when manufacturing.

In its essence, CNC stands for Computer Numerical Control. CNC technology replaces manual processes with automated systems that boost the speed of production and ensure consistency.

Programming is the process of creating a set of codes referred to as M-code or G-code. These codes regulate everything from tool movements to spindle speed, allowing intricate designs to be brought to life with ease.

Knowing the basics of CNC programming can open the door to greater efficiency and creativity in your work. If you can master this technique will allow you to make the most of the potential of different CNC machine tools, while reducing mistakes or waste of materials. Every program is the blueprint to success in making ideas tangible.

The Importance of Accurate Programming for CNC Machines

The accuracy of programming is the basis of the success of CNC manufacturing. It has a direct impact on the quality and accuracy that the finished product.

If programs are accurate they can run machines efficiently. This results to lower production errors and less material waste. Incorrect programming is often the cause of expensive reworks or parts that are scrapped.

Moreover, accuracy enhances machine longevity. If CNC machines function exactly as they are supposed to, they will experience less wear and wear. This results in lower cost of maintenance over time.

In today’s competitive marketplace providing high-quality products in a short time will distinguish businesses. The precise programming can speed up turnaround time without losing quality.

In addition, accurate codes enable greater collaboration between teams working with different CNC machines across various places or platforms such as online CNC machine tools. The clear communication that is provided by well-written programs can ensure everyone is on the same page while creating complicated design.

Key Factors to Consider in CNC Programming

When you are preparing to learn CNC programming, a number of factors require your attention. First, you must consider the selection of the material. Different materials require different approaches for feeds and tooling.

Then, think about the capabilities of the machine. Every CNC machine has particular strengths and weaknesses. Being aware of these could prevent costly errors.

Selection of the right tool is another important aspect. The right tool for cutting increases precision and efficiency while also reducing wear on the tools.

Programming languages play an important function. Learn to use G-code or M-code to ensure a smooth and seamless communication between you and your machine.

Pay pay attention to the setup procedure. A proper calibration ensures that measurements remain precise throughout production runs and leads to the same results over time.

Tips for Efficient CNC Programming

A speedy CNC programming can drastically improve the efficiency of your workflow. Begin with organizing the code in logical order. A well-structured program is much easier to comprehend and troubleshoot.

Use subroutines as often as you can. This permits the user to duplicate code-snippets to save time and reducing the chance of errors within your projects.

Make sure you double-check the tool path before operating the machine. Small errors can result in to serious problems on the floor of the shop.

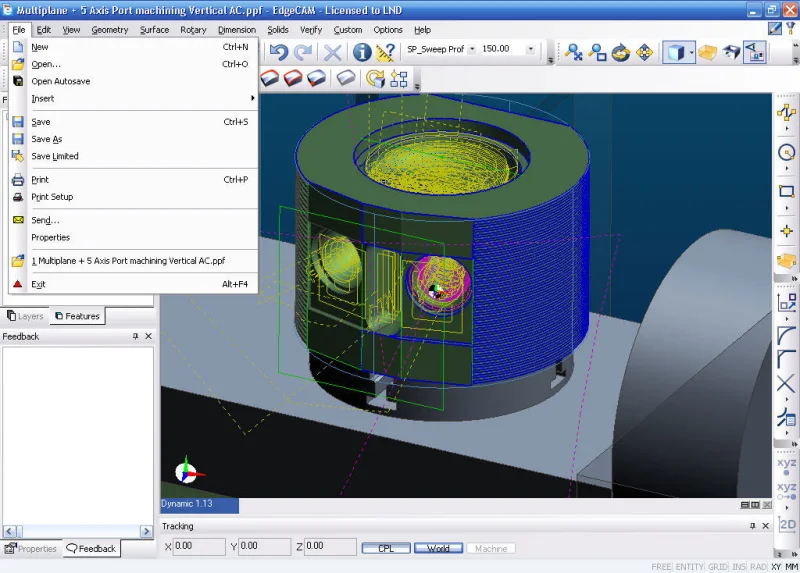

Make use of the simulation software included with a variety of CNC programmers. This allows you to visualise the process of machining and spot potential issues before the actual production process begins.

Think about post-processing options that increase efficiency without sacrificing quality. The ability to tailor these settings to specific tasks can greatly improve efficiency.

Stay informed about the latest developments in CNC techniques and computer features frequently. Becoming informed will allow you to implement new methods that will contribute to productivity over time.

Common Mistakes to Avoid in CNC Programming

The most frequently encountered errors when it comes to CNC programming is not noticing offsets for the tool. By not paying attention, you can result to inaccurate results and costly errors when cutting.

Another error that is frequently made occurs when programmers are unable to simulate their toolpaths. In the majority of cases, omitting this crucial step causes collisions or waste of materials, which can impact the overall effectiveness.

Incorrectly defining working coordinate systems correctly is an additional error. Making sure your setup is in alignment with the machine’s specifications is essential for accuracy.

It’s easy to become involved in complicated programming, but simplicity is key. Complex programs can lead to mistakes and create difficulties in troubleshooting.

The inability to listen to feedback from workers in the shop can have a negative impact on the business. Their feedback is invaluable in improving processes and ensuring the best performance of CNC machine tools.

Using Advanced Features and Software for Better Results

Utilizing the latest CNC programs can drastically enhance your projects in machining. They usually include features that are that are designed to increase precision and speed up time to market.

One of the most impressive features is the simulation. By visualizing the path of the tool prior to the actual process, you are able to detect potential problems without spending time or resources. This preventative approach reduces the chance of costly mistakes.

Another important feature is automation. Modern CNC programming software allows for batch processing, in which many parts can be programmed in parallel. This streamlines workflow and increases productivity.

The integration of CAD/CAM systems plays an important role in getting greater outcomes. A seamless data transfer between manufacturing and design ensures that the design created on the screen will be translated into accurate physical components.

Do not overlook cloud-based solutions too. They provide the remote accessibility to any of your work, which facilitates collaboration between team members no matter their geographical location. This allows for innovation, while ensuring everyone is on the same page with the same goals.

Conclusion

CNC programming is not simply a technical ability; it’s an art that combines accuracy and imagination. If you are able to understand the complexities involved in CNC programming and making use of various tools for programming, you can greatly improve efficiency and precision.

Correct programming is vital to producing high-quality results on any machining task. Focusing on important factors such as feeding rates, tool selection and spindle speed will ensure that your ideas are translated seamlessly into the real world.

Implementing the best practices for programming can streamline your work flow. This is a good way to leverage the advanced capabilities of modern CNC programmers to make repetitive work easier or improve routes for machining.

But, it’s equally crucial to keep an eye on the common errors that can impede advancement. Making sure you don’t make mistakes like ignoring specifications for materials or not recognizing machine capabilities could reduce time and energy.

As technology develops, the adoption of the latest CNC tools for machining opens possibilities of advancement for manufacturing. Making use of online CNC machines permits professionals to gain access to expertise that is not available to their immediate group while maximizing production times.

By prioritizing efficiency and accuracy throughout the CNC programming process, manufacturers not only improve product quality but also enhance overall operational effectiveness–setting themselves apart in a competitive landscape where every detail matters.

Ti potrebbe interessare:

Segui guruhitech su:

- Google News: bit.ly/gurugooglenews

- Telegram: t.me/guruhitech

- X (Twitter): x.com/guruhitech1

- Bluesky: bsky.app/profile/guruhitech.bsky.social

- GETTR: gettr.com/user/guruhitech

- Rumble: rumble.com/user/guruhitech

- VKontakte: vk.com/guruhitech

- MeWe: mewe.com/i/guruhitech

- Skype: live:.cid.d4cf3836b772da8a

- WhatsApp: bit.ly/whatsappguruhitech

Esprimi il tuo parere!

Ti è stato utile questo articolo? Lascia un commento nell’apposita sezione che trovi più in basso e se ti va, iscriviti alla newsletter.

Per qualsiasi domanda, informazione o assistenza nel mondo della tecnologia, puoi inviare una email all’indirizzo [email protected].

Scopri di più da GuruHiTech

Abbonati per ricevere gli ultimi articoli inviati alla tua e-mail.