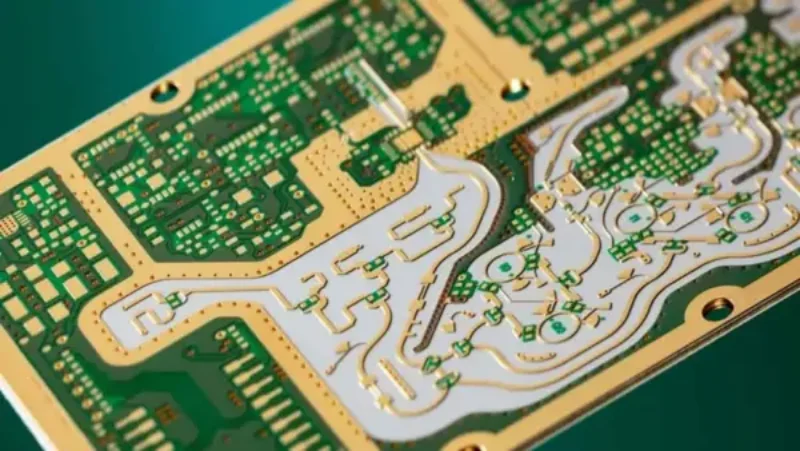

Enhancing Microwave Radar Performance with Advanced Rogers Materials: Low-Loss and High-Frequency Solutions

In the rapidly evolving landscape of radar technology, the pursuit of enhanced performance, reliability, and efficiency has led engineers and designers to focus increasingly on the fundamental building blocks of these systems: the materials used in their construction. Among the industry leaders in this specialized field, Rogers Corporation has established itself as a pioneer in developing advanced materials specifically engineered to meet the demanding requirements of modern microwave radar applications.

This article wrote by RayPCB examines how Rogers’ specialized materials are transforming radar performance through their exceptional low-loss properties and high-frequency capabilities, enabling next-generation radar systems across defense, automotive, aviation, and weather monitoring applications.

The Critical Role of Materials in Radar System Performance

Radar systems operate on the principle of transmitting electromagnetic waves and analyzing their reflections to detect, locate, and track objects. The effectiveness of these systems is directly influenced by the materials used in their construction, particularly in the following critical areas:

Signal Integrity and Detection Range

The primary function of any radar system—detecting and tracking targets at maximum possible ranges—depends heavily on signal integrity. Material losses in the transmission path directly impact the radar’s effective range and sensitivity by attenuating both transmitted and received signals.

Every decibel of loss in the signal path translates to a significant reduction in detection range. According to the radar range equation, a 1 dB improvement in system loss can increase detection range by approximately 12%. In high-stakes applications like military surveillance or air traffic control, this difference can be critical.

Resolution and Discrimination Capabilities

Modern radar applications increasingly demand finer resolution and superior discrimination capabilities to differentiate between closely spaced objects or to identify small targets against cluttered backgrounds. These capabilities require operation at higher frequencies and wider bandwidths, placing even greater demands on the material properties.

Reliability Under Extreme Conditions

Radar systems often operate in challenging environmental conditions, from the extreme cold of high altitudes to the corrosive salt spray of maritime environments, and from the scorching heat of desert deployments to the vibration-intensive environment of moving vehicles. The materials used must maintain consistent electrical properties and physical integrity across these diverse conditions.

Fundamentals of Low-Loss Materials for Microwave Applications

Before exploring specific Rogers materials, it’s important to understand what makes a material “low-loss” and why this property is crucial for radar performance.

Dielectric Loss Mechanisms

Dielectric loss in radar circuit materials primarily occurs through:

- Dipole relaxation losses: Energy dissipation due to molecular dipole reorientation in response to alternating electric fields

- Conduction losses: Energy losses from free charge carriers moving through the material

- Vibrational and resonance losses: Energy absorption by molecular vibrations, particularly at specific frequencies

These mechanisms are quantified through the material’s dissipation factor (tanδ), with lower values indicating superior performance. For high-performance radar applications, materials with dissipation factors below 0.002 at operating frequencies are typically preferred.

Impact of Loss Tangent on Radar Performance

The loss tangent directly affects:

- Signal-to-noise ratio (SNR): Lower loss materials preserve signal strength, improving the radar’s ability to detect weak returns from distant or small targets

- Power requirements: Lower loss materials reduce the transmitter power needed to achieve specific detection ranges, enabling smaller, more efficient systems

- Thermal management: Lower loss materials generate less heat under high-power conditions, improving reliability and reducing cooling requirements

Rogers’ Advanced Material Solutions for Radar Applications

Rogers Corporation has developed several families of materials specifically engineered to address the unique challenges of microwave radar applications. Each family offers distinct advantages for specific use cases.

RT/duroid® Series: Setting the Standard for Low-Loss Performance

The RT/duroid® series represents Rogers’ flagship offering for the most demanding radar applications, with several variants optimized for specific requirements:

RT/duroid® 5880

This glass microfiber-reinforced PTFE composite features:

- Extremely low dielectric constant (2.20) with minimal variation across frequencies

- Exceptionally low dissipation factor (0.0009 at 10 GHz)

- Low moisture absorption (0.02%)

- Stable electrical properties over wide temperature ranges

These properties make RT/duroid 5880 particularly valuable for airborne radar systems where weight, performance, and reliability under varying conditions are critical. The material has become the industry standard for many military and commercial aviation radar applications, from synthetic aperture radar (SAR) systems to weather radar arrays.

RT/duroid® 6002

For applications requiring higher dielectric constant with minimal sacrifice in loss performance, RT/duroid 6002 offers:

- Dielectric constant of 2.94 ± 0.04

- Low dissipation factor (0.0012 at 10 GHz)

- Ceramic-filled PTFE composition for improved mechanical stability

- Excellent dimensional stability during processing

This material is frequently specified for phased array radar applications where consistent electrical properties across the entire antenna array are essential for precise beam steering and target location.

RO4000® Series: Balancing Performance and Processability

The RO4000® series bridges the gap between high-performance PTFE-based materials and conventional FR-4 epoxy materials, offering an excellent balance of electrical performance and manufacturing efficiency.

RO4350B™

This material features:

- Dielectric constant of 3.48 ± 0.05 at 10 GHz

- Low dissipation factor (0.0037 at 10 GHz)

- Hydrocarbon ceramic laminate compatible with standard FR-4 processing

- High thermal conductivity for improved power handling

RO4350B has gained significant adoption in commercial radar applications, particularly in automotive radar systems operating at 24 GHz and 77-81 GHz bands for advanced driver assistance systems (ADAS). Its ability to be processed using standard PCB manufacturing techniques significantly reduces production costs while still delivering the necessary electrical performance for short to medium-range radar applications.

RO4835™

Developed specifically for high-power applications, RO4835 offers:

- Improved oxidation resistance for long-term reliability

- Dielectric constant of 3.48 ± 0.05 at 10 GHz

- Dissipation factor of 0.0037 at 10 GHz

- Enhanced resistance to CAF (Conductive Anodic Filament) formation

- Excellent thermal stability

These properties make it particularly suitable for high-power radar transmitters where thermal management and long-term reliability are critical considerations.

TMM® Series: Temperature-Stable Ceramic Solutions

For applications requiring exceptional temperature stability, the TMM® (Thermoset Microwave Materials) series offers ceramic-loaded thermoset polymer composites with remarkable consistency across wide temperature ranges.

TMM®10

This material features:

- Dielectric constant of 9.2 ± 0.23

- Low dissipation factor (0.0022 at 10 GHz)

- Thermal coefficient of dielectric constant near zero

- High thermal conductivity (0.76 W/m/K)

- Excellent dimensional stability

The high dielectric constant makes TMM10 particularly valuable for applications requiring miniaturization or reduction of antenna elements, such as compact phased array systems for naval vessels or ground-based installations where space constraints exist.

Design Considerations for Optimal Radar Performance

Simply selecting advanced materials is only the first step in enhancing radar performance. Engineers must consider several additional factors when designing microwave radar circuits with these materials.

Impedance Control and Transmission Line Design

Precise impedance control is critical for minimizing reflections and maximizing power transfer in radar systems. Rogers materials facilitate this through:

- Tight dielectric constant tolerance across the material

- Excellent thickness control

- Low profile copper options with reduced surface roughness

For example, when designing microstrip transmission lines on RT/duroid 5880 for a 77 GHz automotive radar application, the conductor width must be precisely controlled to maintain the required 50-ohm impedance. The material’s consistent dielectric properties ensure that this impedance remains stable across the entire circuit.

Thermal Management Strategies

High-power radar transmitters generate significant heat that must be effectively managed to ensure reliability. Strategies include:

- Utilizing materials with higher thermal conductivity, such as the RO4000 series

- Incorporating thermal vias to conduct heat to ground planes

- Designing copper features to act as heat spreaders

- Combining Rogers materials with metal-backed substrates for enhanced heat dissipation

Manufacturing Process Optimization

To fully realize the performance benefits of advanced materials, manufacturing processes must be optimized:

- Specialized drilling and cutting techniques for PTFE-based materials

- Appropriate surface preparation methods for reliable metallization

- Optimized lamination cycles to ensure proper adhesion without degrading electrical properties

- Controlled impedance fabrication processes with verification testing

Application-Specific Material Solutions

Different radar applications present unique challenges that can be addressed through specific material selections and design approaches.

Military and Defense Radar Systems

Military radar systems often operate at X-band (8-12 GHz) and Ku-band (12-18 GHz) frequencies, requiring:

- Extremely low-loss materials for maximum detection range

- High reliability under harsh environmental conditions

- Resistance to vibration and mechanical stress

For these applications, RT/duroid 5880 or 6002 laminates are often specified, with their exceptional electrical performance and proven reliability in mission-critical systems. These materials enable the development of long-range surveillance radar, targeting radar, and electronic warfare systems that require maximum sensitivity and range.

Automotive Radar for Advanced Driver Assistance Systems

Modern automotive radar systems operate primarily in the 77-81 GHz range, presenting challenges including:

- Cost-sensitive production requirements

- Compact packaging constraints

- Wide temperature operation range (-40°C to +125°C)

- High volume manufacturing needs

The RO4000 series, particularly RO4350B and RO4830, offer an ideal balance of performance and processability for these applications. Their compatibility with standard PCB manufacturing processes enables cost-effective production of millimeter-wave radar modules that power adaptive cruise control, collision avoidance, and blind-spot detection systems.

Weather and Meteorological Radar

Weather radar systems, typically operating in the C-band (4-8 GHz) or S-band (2-4 GHz), require:

- Exceptional stability over time and environmental conditions

- High power handling for long-range transmission

- Precise phase control for Doppler measurements

Materials like RT/duroid 6010 with its higher dielectric constant (10.2) enable more compact antenna designs while maintaining excellent electrical performance, ideal for phased array weather radar systems that require numerous radiating elements in a confined space.

Aviation and Airborne Radar

Airborne radar systems face unique constraints:

- Weight sensitivity

- Operation across extreme temperature ranges

- Vibration and mechanical stress

- Reliability requirements for safety-critical applications

RT/duroid 5880, with its low density (1.4 g/cm³) and exceptional electrical performance, has become the standard material for many airborne radar applications. Its low moisture absorption also ensures consistent performance across varying humidity conditions experienced at different altitudes.

Future Trends in Radar Materials Development

As radar technology continues to evolve, materials science is advancing to meet emerging requirements:

Higher Frequency Operation

The push toward higher frequencies for improved resolution and reduced antenna size is driving development of materials with:

- Even lower loss at millimeter-wave frequencies (30-300 GHz)

- Improved copper foil technology with ultra-low profile and reduced roughness

- Enhanced consistency of dielectric properties across wide frequency ranges

Integrated Multi-function Systems

Modern radar platforms increasingly combine multiple functions (communications, radar, electronic warfare) in a single system, requiring:

- Materials compatible with complex, multi-layer designs

- Solutions for integrating different material types in hybrid constructions

- Improved thermal management for densely packed electronics

Environmental Sustainability

Increasing focus on environmental impact is driving development of:

- Halogen-free material options

- Manufacturing processes with reduced environmental footprint

- Materials compliant with evolving global regulations

Case Studies: Material Selection Impact on Radar PerformanceCase Study 1: Automotive Collision Avoidance Radar

A leading automotive supplier transitioning from 24 GHz to 77 GHz radar technology for improved resolution faced challenges with their existing FR-4 based design. By switching to Rogers RO4350B material, they achieved:

- 40% reduction in transmission line losses

- Improved detection reliability at ranges beyond 200 meters

- Enhanced resistance to environmental factors affecting long-term performance

- Compatibility with existing manufacturing processes requiring minimal retooling

This material change enabled the development of a new generation of collision avoidance systems with significantly improved performance while maintaining competitive production costs.

Case Study 2: Military Airborne Surveillance Radar

A defense contractor developing an X-band airborne surveillance radar needed to maximize range while minimizing weight. By utilizing RT/duroid 5880 laminates, they achieved:

- 15% increase in detection range compared to previous generation materials

- 12% weight reduction in the antenna array structure

- Consistent performance across operating temperatures from -55°C to +125°C

- Improved reliability in high-humidity conditions

The enhanced performance enabled the radar to detect smaller targets at greater distances, significantly improving mission capabilities.

Conclusion

The selection of appropriate circuit materials represents one of the most fundamental yet impactful decisions in radar system design. As radar applications continue to demand greater performance, reliability, and efficiency, advanced materials like those developed by Rogers Corporation provide engineers with the tools to push the boundaries of what’s possible.

From the exceptional low-loss properties of RT/duroid materials enabling maximum detection ranges to the processing efficiency of RO4000 series enabling cost-effective automotive radar solutions, these specialized materials address the unique challenges of diverse radar applications. By understanding the specific requirements of their applications and selecting materials accordingly, designers can significantly enhance radar performance while meeting operational, environmental, and economic constraints.

As radar technology continues its rapid evolution toward higher frequencies, greater integration, and enhanced capabilities, the continued development of advanced materials will remain a critical enabler, ensuring that the foundation upon which these systems are built remains as advanced as the technological innovations they support.

Ti potrebbe interessare:

Segui guruhitech su:

- Google News: bit.ly/gurugooglenews

- Telegram: t.me/guruhitech

- X (Twitter): x.com/guruhitech1

- Bluesky: bsky.app/profile/guruhitech.bsky.social

- GETTR: gettr.com/user/guruhitech

- Rumble: rumble.com/user/guruhitech

- VKontakte: vk.com/guruhitech

- MeWe: mewe.com/i/guruhitech

- Skype: live:.cid.d4cf3836b772da8a

- WhatsApp: bit.ly/whatsappguruhitech

Esprimi il tuo parere!

Che ne pensi di questa notizia? Lascia un commento nell’apposita sezione che trovi più in basso e se ti va, iscriviti alla newsletter.

Per qualsiasi domanda, informazione o assistenza nel mondo della tecnologia, puoi inviare una email all’indirizzo [email protected].

Scopri di più da GuruHiTech

Abbonati per ricevere gli ultimi articoli inviati alla tua e-mail.