Fixtures in Automotive Manufacturing: Types, Functions, and Innovations

Introduction

Automotive manufacturing is an intricate process combining precision, technology and innovation. When competing in this highly-competitive industry, fixtures often make all the difference between smooth production lines and costly delays; their function cannot be underestimated! Fixtures play an invaluable role in helping components fit seamlessly together while upholding quality standards.

CMM fixtures provide accurate measurement while auto-checking fixtures offer quick inspections. Both types serve essential functions in automotive assembly processes. As manufacturers strive for efficiency and excellence, understanding these fixtures’ types and functions becomes paramount. Come join us as we delve into automotive manufacturing fixtures – their importance, benefits, innovations – as well as what lies in store!

Importance of Fixtures in the Manufacturing Process

Fixtures play a vital function in manufacturing automotive. They offer stability and precision in the manufacturing process. This is vital to ensure that the parts are able to be joined effortlessly.

In holding the components in a secure manner fixtures reduce the chance of mistakes and defects. Without them, manufacturers could be faced with increased costs for rework and extended production times. Quality consistency becomes more simple to be achieved.

Additionally, fixtures improve workers’ safety by reducing hand-handling of large or oddly shaped components. Workers can concentrate on their job without having to worry about misalignment or slips that happen accidentally.

Additionally to increasing efficiency, top-quality fixtures also contribute to speedier time to cycle. This enables companies to respond to the demands of customers more efficiently while preserving the highest standards.

A strong fixture design results in more efficiency and profit for automobile manufacturers around the world.

Types of Fixtures Used in Automotive Manufacturing

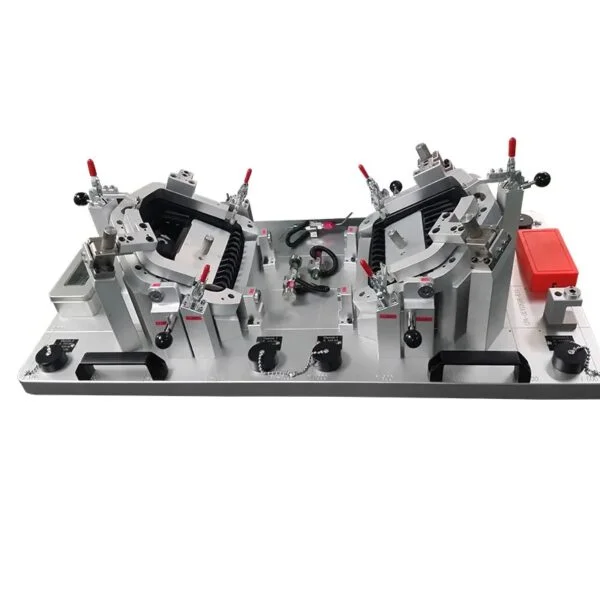

Automotive manufacturing utilizes various fixtures to streamline production and enhance precision. These include coordinate measuring machine (CMM) fixtures that support their machines. This ensures each component satisfies stringent quality standards.

Auto checking fixtures are another essential category. Conceived as quick inspection tools, auto checking fixtures enable manufacturers to spot potential flaws quickly in production processes. This helps cut downtime and enhances efficiency through rapid assessments.

Welding fixtures play a pivotal role in assembly lines. These specialized devices secure parts during welding processes to ensure precise alignment and reduce errors while withstanding high temperatures while remaining structurally sound.

Each fixture serves its own specific function while working toward one central goal – increasing productivity while not compromising quality. As automotive technology develops, so too do its associated tools.

Functions and Benefits of Using Fixtures

In automotive manufacturing, the application of fixtures is critical for ensuring both dimensional fidelity and operational throughput. By offering static registration, these tools direct multiple processes—such as arc welding and final assembly. They do this by delivering consistent support, geometric control, and resistance to unplanned deflection.

The anchorage subsystem primarily functions to immobilise individual components, thereby mitigating unintended translation or rotation that might introduce dimensional drift or cosmetic discontinuities.

Time reduction is similarly pronounced, as fixtures afford operators expedited loading and positional verification of parts for machining or dimensional verification. The consequent decrease in iterative setup cycles translates to compressed throughput windows.

Coordinate measuring machine (CMM) fixtures elevate measurement fidelity by enforcing metrology reference frames within stated dimensional and geometric tolerances. This embeds a layer of quality assurance that persists throughout the manufacturing sequence.

In welding applications, the fixtures contribute to metallurgical reliability by enforcing the requisite joint gap and root fit-up. This leads to repeatable thermal cycles and enhanced joint strength attributes in the completed assembly.

Auto checking fixtures also facilitate inspections by offering clear reference points for measurement tools, improving overall workflow efficiency.

Latest Innovations in Fixture Technology

Automotive manufacturing technology has witnessed an exciting boom, thanks to innovative fixture technologies that improve efficiency and precision. Smart sensors integrated within cmm fixtures offer real-time data that allow manufacturers to monitor performance as they make adjustments on-the-fly and make necessary corrections immediately.

Innovative modular auto checking fixtures represent another breakthrough. These adaptable systems can quickly reconfigure for different models or components during production shifts to reduce downtime during changes and boost operations significantly. Their adaptability improves operational efficiencies significantly.

3D printing has also made an impactful mark in fixture design. Manufacturers now create lightweight yet sturdy welding fixtures tailored for specific tasks quickly with astonishing speed. This not only saves costs but also expedites prototyping and testing more rapidly than before.

Augmented reality (AR) glasses have begun playing an increasing role in assembly processes. Workers equipped with AR glasses receive visual guidance directly overlaid on their workpieces for accurate assembly lines.

Case Studies: How Fixtures Have Improved Automotive Production

One notable case involves an automaker that successfully implemented advanced auto checking fixtures into its production line. This dramatically shortened time spent performing quality controls while improving turnaround without compromising accuracy or expedience.

An industrial company specializing in welding fixtures experienced marked improvements in alignment and consistency during assembly. Customized fixtures reduced misalignments that often caused costly rework or delays.

An inventive use of CMM (Coordinate Measuring Machine) fixtures was demonstrated. This was through an innovative use in the design phase of CMM fixtures to conduct accurate measurements early in development. It improved product reliability while decreasing material waste during manufacturing processes.

These real-world applications demonstrate how fixture technology not only optimizes workflows but also boosts efficiency across several stages of automotive production. Each success story highlights the transformative influence that intelligently designed fixtures have had on overall productivity.

Challenges and Limitations of Fixtures

Fixtures play an indispensable role in automotive production, yet can present their own set of difficulties. One significant complication lies with initial costs; designing and fabricating high-quality fixtures may require substantial investments from smaller manufacturers that may discourage their participation.

Another challenge lies in adaptability. Changes to vehicle designs or production processes often necessitate fixture redesigns. This leads to downtime and increased costs associated with developing and installing new fixtures.

Precision is of utmost importance but often difficult to attain consistently, leading to defects that compromise safety and performance during assembly processes. Any misalignments could disrupt this crucial aspect.

Maintenance plays an integral part in production. Fixtures become worn over time; therefore regular upkeep becomes even more essential in today’s production environments. Failing to do this correctly could result in additional delays or compromised quality standards and could ultimately compromise customer expectations.

Fixture Design Trends to Look Out for in the Near Future

Future fixture design trends in automotive production look promisingly progressive. As automation and smart technologies progress, fixtures will become ever more advanced.

Integrating IoT devices allows for real-time data collection, increasing monitoring and precision during production processes. Auto checking fixtures linked with analytics systems help manufacturers quickly spot inefficiencies more efficiently.

Materials engineering is also rapidly progressing. Lightweight yet resilient composites may soon replace heavy metals in fixture construction projects – not only saving costs and increasing overall efficiency.

3D printing technology represents yet another innovation frontier. It provides customized fixtures tailored specifically for specific components or processes to be produced on demand. This decreases lead times and waste significantly.

As electric vehicle adoption increases, so too will demand for specialized welding fixtures that effectively handle new materials such as aluminum and high-strength steel. Innovation in this space should focus on handling these new materials efficiently.

These trends represent the dynamic environment facing fixture design within automotive production.

Conclusion

Fixtures play an indispensable role in automotive production, ensuring precision and efficiency during every phase of manufacturing. Manufacturers can maximize production capabilities by becoming knowledgeable about various fixtures. CMMs, auto checking devices, and welding fixtures are just a few examples. These help improve production capabilities by improving accuracy, streamlining operations, and cutting costs.

Recent advances in fixture technology have created new avenues of productivity and quality assurance. It opens up even greater potential in productivity and quality assurance for industries using automation technology and advanced materials. It is likely that even more complex designs may emerge soon enough.

Although initial setup costs and maintenance present challenges, ongoing advances offer hope of effectively addressing them. It’s clear that fixture design plays an integral part in shaping automotive manufacturing in the coming decades.

Acknowledging these developments could give manufacturers an edge in an ever-evolving market. Any company seeking excellence in automotive assembly lines needs to understand how various fixtures contribute to enhanced production processes. Additionally, they need to understand how different fixtures impact production procedures.

Ti potrebbe interessare:

Segui guruhitech su:

- Google News: bit.ly/gurugooglenews

- Telegram: t.me/guruhitech

- X (Twitter): x.com/guruhitech1

- Bluesky: bsky.app/profile/guruhitech.bsky.social

- GETTR: gettr.com/user/guruhitech

- Rumble: rumble.com/user/guruhitech

- VKontakte: vk.com/guruhitech

- MeWe: mewe.com/i/guruhitech

- Skype: live:.cid.d4cf3836b772da8a

- WhatsApp: bit.ly/whatsappguruhitech

Esprimi il tuo parere!

Ti è stato utile questo articolo? Lascia un commento nell’apposita sezione che trovi più in basso e se ti va, iscriviti alla newsletter.

Per qualsiasi domanda, informazione o assistenza nel mondo della tecnologia, puoi inviare una email all’indirizzo [email protected].

Scopri di più da GuruHiTech

Abbonati per ricevere gli ultimi articoli inviati alla tua e-mail.